Team:ETH Zurich/Modeling/Chemostat Selection

From 2008.igem.org

Chemostat SelectionAs mentioned in the Project Overview page, one of the main concepts in our project is the possibility to select for organisms with reduced genome size. To achieve this we have thought of letting our system develop in a continuous environment with nucleotide limitation and base the selection method on the difference in growthrate. The aim of this model is to show the applicability of this concept and to determine the parameters for the operation of the chemostat in the lab. The questions we are trying to adress with this model are:

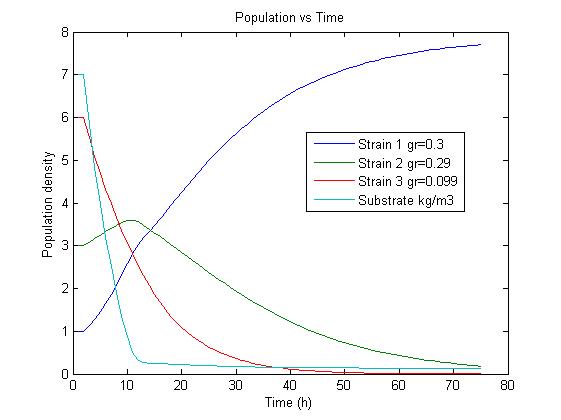

We obtain the results for the calculated growth rates form the flux balance analysis performed in section Genome-Scale Model for the random deletions. These simulations performed on the different strains in our chamostat are used to simulate the development of the population concentrations in continuous culture. The goal is to build a model in which we can vary parameters like population growth rates, feed concentration and dilution rate to optimize the operation of the continuous culture in the lab.

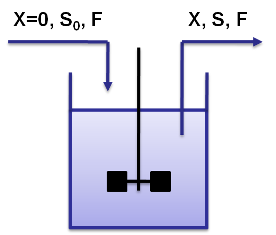

Cemostat basicsA chemostat allows for continuous fermentation in a constant volume. It consists of a culture vessel with an input aperture for sterile medium and an overflow aperture to mantain the volume constant. This allows to mantain a constant population in the chemostat but still have continuous cell division.

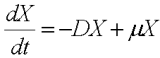

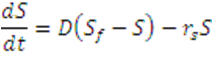

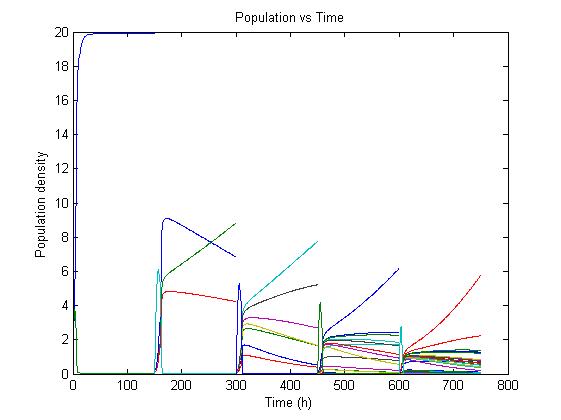

Here X is the concentration of biomass in kg/m3, S0 the feed concentration in kg/m3 and F Feed in l/h. By varying parameters like the dilution rate (D) and the concentration of nutrients in the medium, different steady states can be obtained, thus allowing to fine tune the selection process. In our case, the feed rate can be set externally and cell growth is limited by a selected nutrient (in our case nucleotides). The specific growth rate in the chemostat can be determined by the material mass balances of biomass and substrate. (Rate of accumulation)=(Input rate) - (Output rate) + (Production rate) The equation for biomass is given by: Where X is the biomass in kg/m3, D the dilution rate in 1/h given by the Monod equation, mu is the growth rate in 1/h, Sf is the feed concentration, S is the substrate concentration and rs substrate rate. Competition in the chemostatWe have extended the basic chemostat model to allow for selection of strains with reduced genome sizes by inluding mass balances for the biomass of more than one strain. We couple the differential equations in order to let the strains compete for the available limiting substrate. By changing parameters like the different growth rates of the different populations or the dilution rate we can variate the parameters and optimize the selection mechanism. We are interested in the effects of differences in growth rate and dilution rates on the sensitivity of our method to validate our assumptions. In this figure we observe three different strains competing in the chemostat. We can observe 3 differnt scenarios. In the first case, Strain 1 has the highest growth rate and as expected after some time reaches the highest biomass in the reactor, allthough the initial concentration is the smallest. Strain 2 has a higher biomass concentration at the beginning, but due to the slightly smaller growthrate is eventually outgrown by strain 1. Strain 3 has a growthrate that is smaller than the dilution rate and thus is washed out irrespective of the initial concentration. The simulation results confirm our assumtions that a selection for strains showing different growthrates is possible under adequate conditions. PulseReferences |

"

"