Team:Paris/Perspectives

From 2008.igem.org

| Line 1: | Line 1: | ||

{{Paris/Menu}} | {{Paris/Menu}} | ||

| + | {{Paris/Header|Perspectives}} | ||

Latest revision as of 04:52, 30 October 2008

|

Perspectives

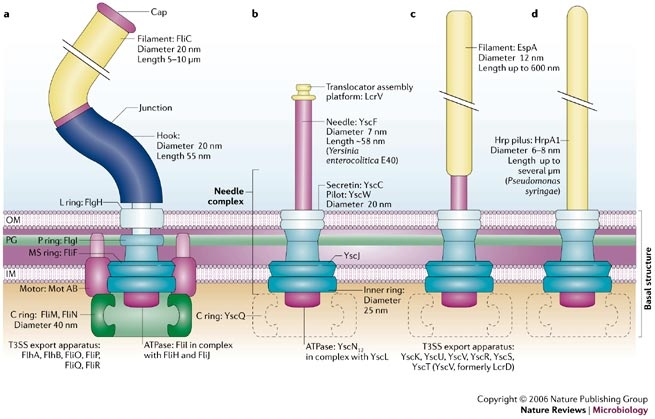

Example 1: type III secretion injectisomeThe injectisome is a complex nanomachine that allows bacteria to deliver protein effector across eucaryotic cellular membranes. The injectisome consists of a basal structure, which resembles the basal structure of the flagellum, surmounted by either a needle, a needle and a filament or a long pilus.

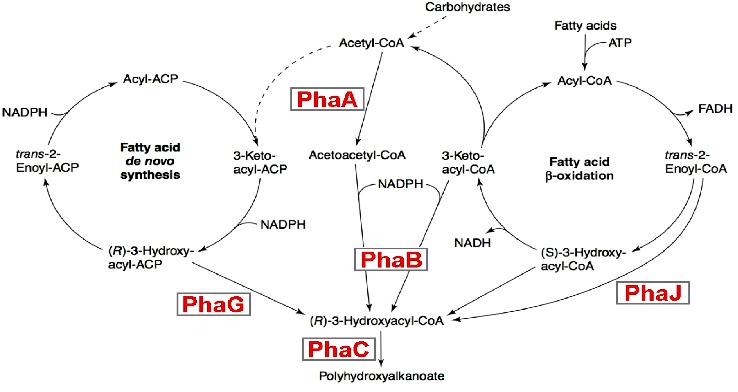

In conclusion, our BacteriO'Clock can be used in a lot of new applications like for instance, bottom-up molecular machines self-assembly or new kinds of optimized chemoreactor. Example 2: metabolic engineering of polyhydroxyalkanoate biosynthesis pathwaysHuman overpopulation combined with the current lifestyle urges the rational, efficient, and sustainable use of natural resources to produce environmentally friendly plastic materials. One illustrative example is polyhydroxyalkanoic acids (PHAs), whose production/degradation cycle reduces undesirable wastes and emissions. The biosynthesis of this polymer is currently subject to intensive work. It consists in expressing in appropriate quantities 3 enzymes PhaA ,PhaB and PhaC that sequentially process AcetoacetylcoA into its final product PHA. This biosynthesis os subjected to 2 constraints :

Two strategies are commonly used in bioengineering of metabolic pathways :

Because of the above mentioned limitations, none of these approaches are adapted here . Using the sequential expression, intermediate products would accumulate and thus be consumed by competing pathways. Using the constitutive expression a mixture of final and intermediate product would necessarily be obtained. Our FIFO could be useful here. Indeed a FIFO expression pattern is intermediate between a purely sequential and a purely constitutive expression. At some point all enzymes are presents ( no accumulation of intermediate products ) and during the last step only the last enzyme (PhC) is presents ( all intermediate products are consumed). Moreover, the fact that our system oscillate could provide to the cell a metabolic recovering phase.

Bibliography

Ilana S Aldor and Jay D Keasling Department of Chemical Engineering, 201 Gilman Hall, University of California, Berkeley, 94720-1462, USA 23 September 2003

Nomura CT, Taguchi S. Department of Chemistry, State University of New York - College of Environmental Science and Forestry, 121 Jahn Laboratory, Syracuse, NY 13210, USA. |

"

"