Team:Harvard/Dailybook/Week1/Widgetry

From 2008.igem.org

(Difference between revisions)

(New page: =Monday: June 23, 2008= ==Lab== * Received ordered parts from McMaster-Carr * Drew preliminary designs for MFC 300px * Cut polycarbonate tubing ** 2" Square T...) |

|||

| Line 3: | Line 3: | ||

* Received ordered parts from McMaster-Carr | * Received ordered parts from McMaster-Carr | ||

* Drew preliminary designs for MFC | * Drew preliminary designs for MFC | ||

| - | [[Image:Mfc_prototype1.jpg|300px]] | + | [[Image:800px-Mfc_prototype1.jpg|300px]] |

* Cut polycarbonate tubing | * Cut polycarbonate tubing | ||

** 2" Square Tubing: | ** 2" Square Tubing: | ||

| Line 14: | Line 14: | ||

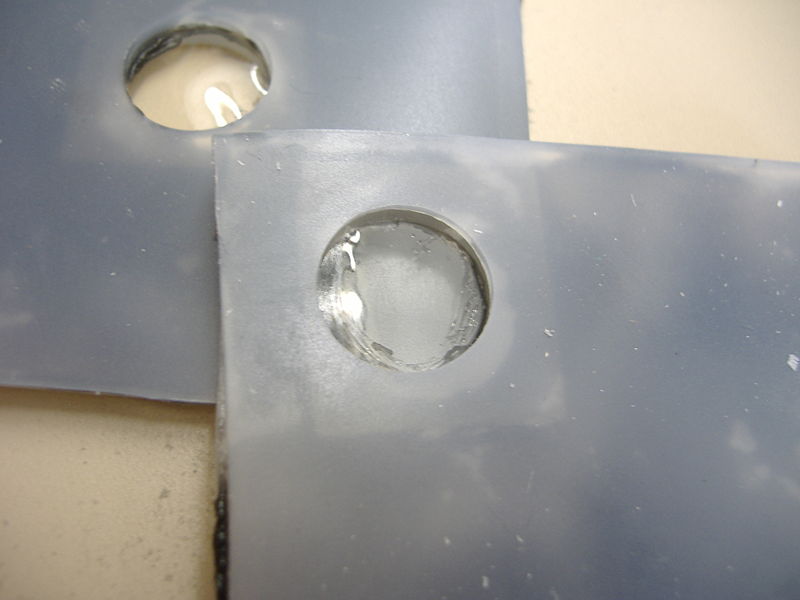

* Tested 5 minute epoxy: | * Tested 5 minute epoxy: | ||

** Attached 1.5" (2" Diameter) polycarbonate square tubing to sheet | ** Attached 1.5" (2" Diameter) polycarbonate square tubing to sheet | ||

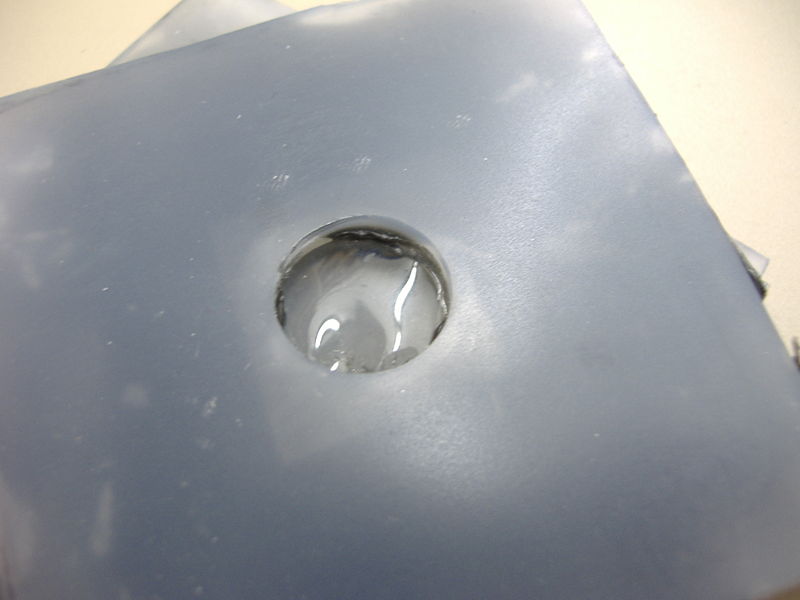

| - | [[Image:Mfc_epoxy.JPG|300px]] | + | [[Image:800px-Mfc_epoxy.JPG|300px]] |

* Tested silicon: | * Tested silicon: | ||

** Attached 1.5" (2" Diameter) polycarbonate square tubing to sheet | ** Attached 1.5" (2" Diameter) polycarbonate square tubing to sheet | ||

| - | [[Image:Mfc_silicon.JPG|300px]] | + | [[Image:800px-Mfc_silicon.JPG|300px]] |

* Tested silver epoxy: | * Tested silver epoxy: | ||

** Attached titanium wire to graphite sheet | ** Attached titanium wire to graphite sheet | ||

| - | [[Image:Mfc_silverepoxy.JPG|300px]] | + | [[Image:800px-Mfc_silverepoxy.JPG|300px]] |

==Results== | ==Results== | ||

| Line 75: | Line 75: | ||

*Milled holes for injection ports and bolts | *Milled holes for injection ports and bolts | ||

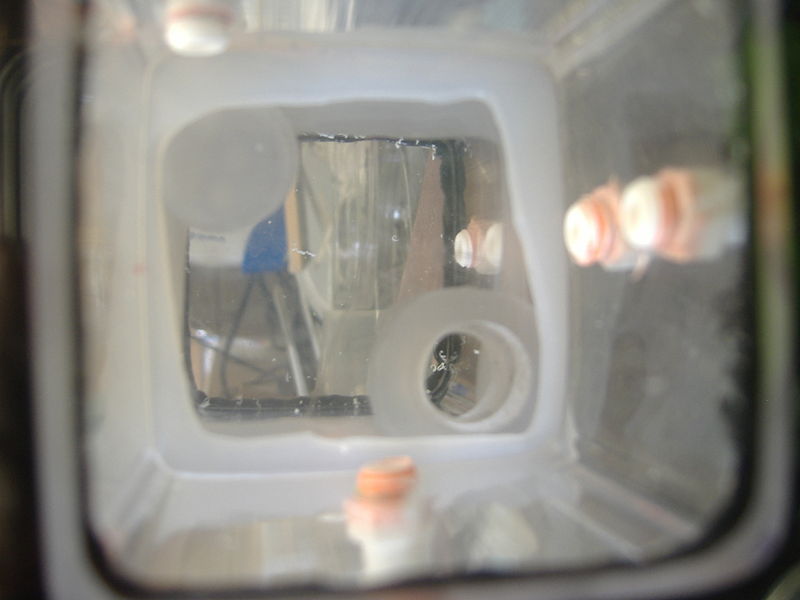

*Assembled prototype for MFC minus anode and membrane | *Assembled prototype for MFC minus anode and membrane | ||

| - | [[Image:Mfc_prototype2.JPG|300px]] | + | [[Image:800px-Mfc_prototype2.JPG|300px]] |

*Make cathode using alternative wiring design to maximize surface area | *Make cathode using alternative wiring design to maximize surface area | ||

*Made another chamber using epoxy for autoclave test | *Made another chamber using epoxy for autoclave test | ||

*Airtight test by submerging pressurized MFC prototype in water | *Airtight test by submerging pressurized MFC prototype in water | ||

** No air bubbles observed | ** No air bubbles observed | ||

| - | [[Image:Mfc_oxygentest.JPG|300px]] | + | [[Image:800px-Mfc_oxygentest.JPG|300px]] |

==Purchased== | ==Purchased== | ||

| Line 142: | Line 142: | ||

**added nafion membrane | **added nafion membrane | ||

**added carbon felt anode | **added carbon felt anode | ||

| - | [[Image:Mfc_prototype3.JPG|300px]] | + | [[Image:800px-Mfc_prototype3.JPG|300px]] |

*membrane did not pass water-tight test | *membrane did not pass water-tight test | ||

| Line 150: | Line 150: | ||

'''''Warped membrane''''' | '''''Warped membrane''''' | ||

| - | [[Image:Mfc_nafionwarped.JPG|300px]] | + | [[Image:800px-Mfc_nafionwarped.JPG|300px]] |

'''''Normal membrane''''' | '''''Normal membrane''''' | ||

| - | [[Image:Mfc_nafionnormal.JPG|300px]] | + | [[Image:800px-Mfc_nafionnormal.JPG|300px]] |

* new MFC: | * new MFC: | ||

| Line 167: | Line 167: | ||

***outer “ring” | ***outer “ring” | ||

***cathode chamber | ***cathode chamber | ||

| - | [[Image:Mfc_prototype4.JPG|300px]] | + | [[Image:800px-Mfc_prototype4.JPG|300px]] |

:* water tight test: | :* water tight test: | ||

:** passed water tight test | :** passed water tight test | ||

| Line 179: | Line 179: | ||

==Lab== | ==Lab== | ||

*Finished building air cathode MFC, minus injection ports | *Finished building air cathode MFC, minus injection ports | ||

| - | [[Image:Mfc_airprototype.JPG|300 px]] | + | [[Image:800px-Mfc_airprototype.JPG|300 px]] |

*Autoclaved LML | *Autoclaved LML | ||

=== Keithley test === | === Keithley test === | ||

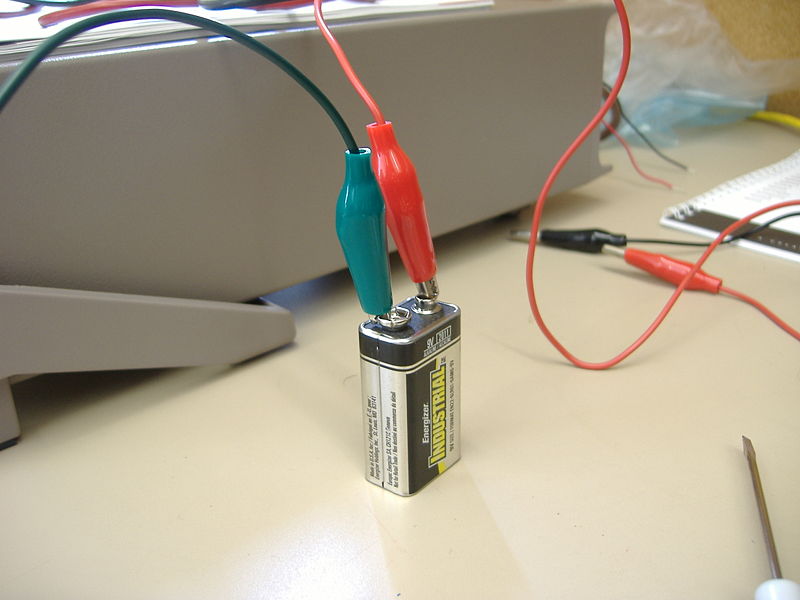

| - | [[Image:Mfc_circuit.JPG|300px]] | + | [[Image:800px-Mfc_circuit.JPG|300px]] |

* Connected simple battery-resistor circuit to both 2700 alone and with 7700 switching module | * Connected simple battery-resistor circuit to both 2700 alone and with 7700 switching module | ||

** Used 8.78 V source of 4M ohm resistance with 1% accuracy | ** Used 8.78 V source of 4M ohm resistance with 1% accuracy | ||

Latest revision as of 17:49, 28 October 2008

Contents |

Monday: June 23, 2008

Lab

- Received ordered parts from McMaster-Carr

- Drew preliminary designs for MFC

- Cut polycarbonate tubing

- 2" Square Tubing:

- Three 1.5" sections

- Two 3" sections

- 3" Round Tubing:

- Four 2" sections

- Polycarbonate sheets:

- Four 3x3" squares

- 2" Square Tubing:

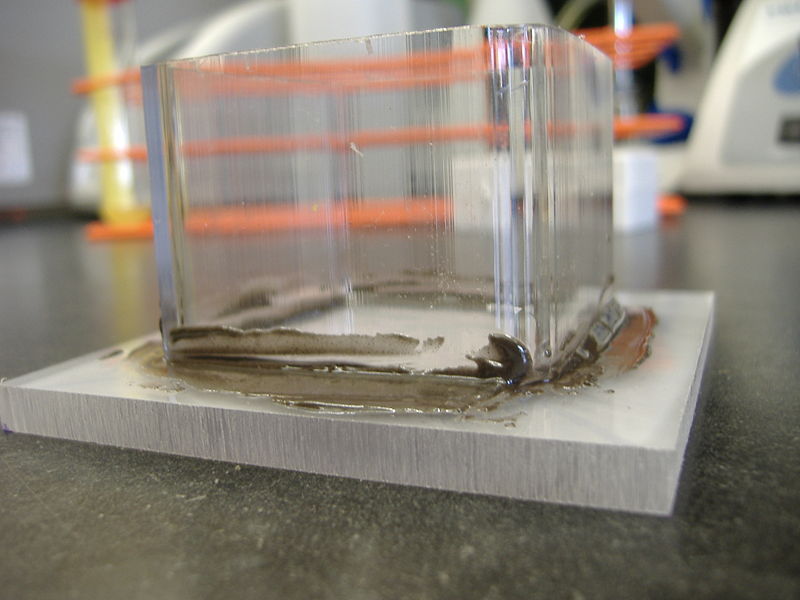

- Tested 5 minute epoxy:

- Attached 1.5" (2" Diameter) polycarbonate square tubing to sheet

- Tested silicon:

- Attached 1.5" (2" Diameter) polycarbonate square tubing to sheet

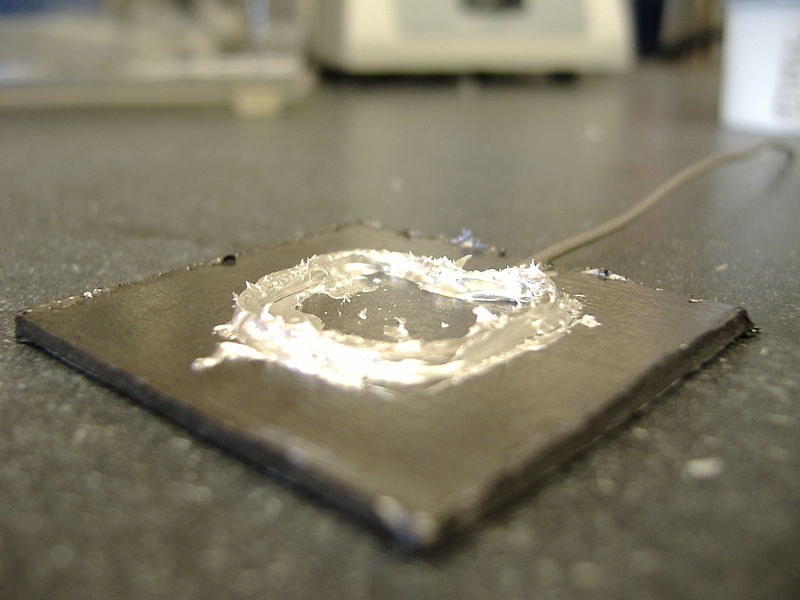

- Tested silver epoxy:

- Attached titanium wire to graphite sheet

Results

Silicon

- questionable adhesiveness

Epoxy

- fairly strong adhesiveness

Silver epoxy

Resistances:

- Wire : 0.35 Ω / in

- Graphite: 1 Ω / in

- Across junction: 5 Ω / in

Purchased

From McMaster-Carr

| Qty. | Part |

| 20ft | High-Temperature Silicone Rubber Tubing Soft, 3/16" ID, 3/8" OD, 3/32" Wall, Blue |

| 20ft | High-Temperature Silicone Rubber Tubing Soft, 3/16" ID, 3/8" OD, 3/32" Wall, White |

| 3 (packs of 10) | Aluminum Oxide Cloth Sanding Sheet 280 Grit, 9" X 11" |

| 1 | Bright Finish High-Speed Stl Spiral Point Tap 1/4"-28, H3 Pitch Diameter, 2 Flute |

| 2 (packs of 10) | Plain Steel Fully Threaded Stud 1/4"-20 Thread, 6" Length |

| 3 (packs of 25) | Zinc Alloy Wing Flange Nut 1/4"-20 Screw Size, 1" Wing Spread |

Tuesday: June 24, 2008

Meeting with Peter Girguis

General Design

- Three basic designs:

- Vertical with two chambers stacked

- Vertical with anode and air cathode below

- Horizontal (perhaps with incline)

- Nitrogen/Oxygen bubbling

- Maybe do in flasks outside of actual fuel cell

Lab

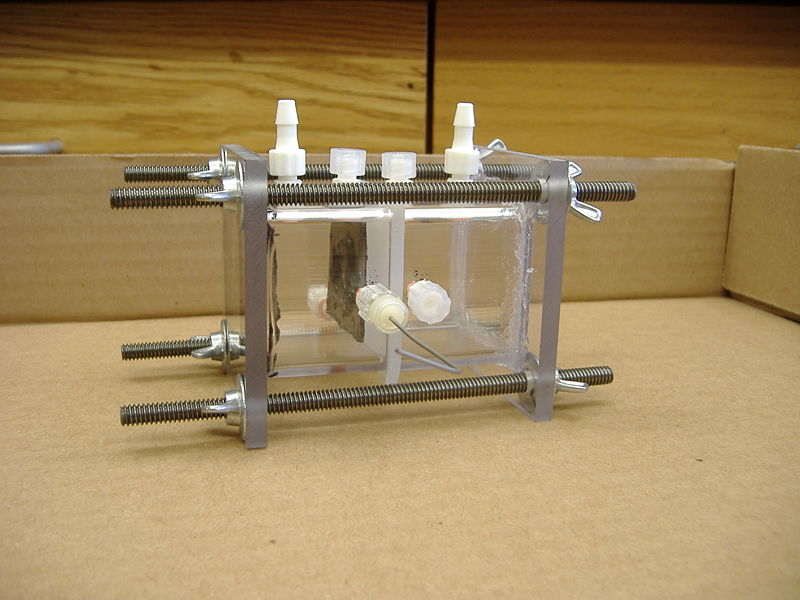

- Milled holes for injection ports and bolts

- Assembled prototype for MFC minus anode and membrane

- Make cathode using alternative wiring design to maximize surface area

- Made another chamber using epoxy for autoclave test

- Airtight test by submerging pressurized MFC prototype in water

- No air bubbles observed

Purchased

From Alfa Aesar

| Qty. | Part |

| 15x15cm | Nafion® membrane, 0.180mm thick |

| 10x10cm | Carbon felt, 6.35mm (0.25in) thick, 99.0% |

Wednesday: June 25, 2008

Lab

- Autoclaved epoxy chamber

- Results:

- Laminated nafion membrane

- Made two black silicone chambers

- Tested MFC by bubbling air into anode chamber to test gas in/out ports

- Result successful.

- Wrapped carbon felt with titanium wire without epoxy

- Resistance:

- Across junction: 2.5 Ω

- Felt: 1.5 Ω

- Resistance:

Received from Peter Girguis:

- Decade resistance box

- Carbon fiber cloth

Purchased

From McMaster-Carr

| Qty. | Part |

| 1 (packs of 10) | Inline Minature Air Regulator 1/4" Female Inlet, 1/4" Male Outlet, 5 Max SCFM |

| 1 (packs of 10) | Brass Barbed Hose Fitting Barb X Male Pipe for 3/16" Hose ID, 1/4" Pipe |

| 1 (packs of 10) | Brass Barbed Hose Fitting Barb X Female Pipe for 3/16" Hose ID, 1/4" Pipe |

| 6 | Polycarbonate Sheet 6" x 6" Sample, 1/4" Thick, Clear |

| 2 Ft. | Polycarbonate Square Tube 2" Square Tube |

| 25 Ft. | High-Temperature Silicone Rubber Tubing Soft, 3/32" ID, 7/32" OD, 1/16" Wall, Blue |

| 25 Ft. | High-Temperature Silicone Rubber Tubing Soft, 3/32" ID, 7/32" OD, 1/16" Wall, White |

Thursday: June 26, 2008

Lab

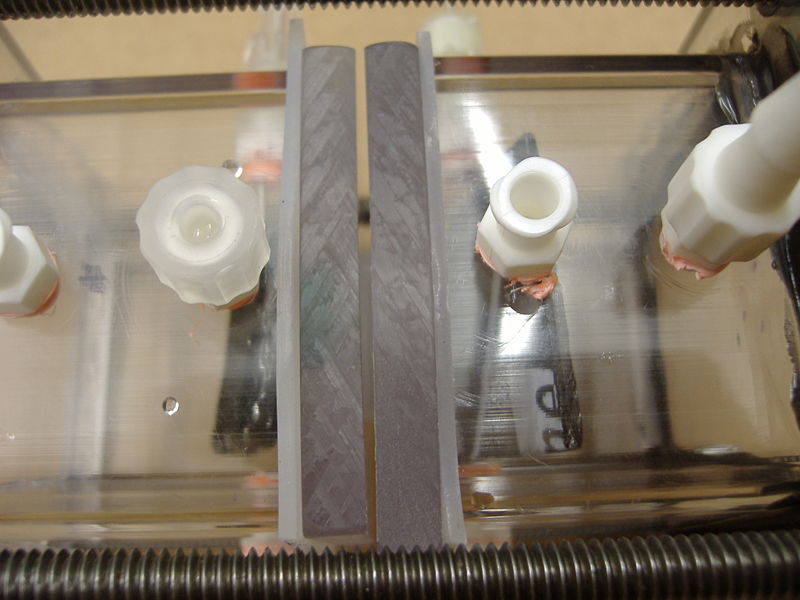

- finished building MFC

- added nafion membrane

- added carbon felt anode

- membrane did not pass water-tight test

- silicon sheet started bulging

- nafion membrane started warping

Warped membrane

Normal membrane

- new MFC:

- design:

- anode chamber

- outer “ring”

- polycarbonate with 15/36” hole

- smaller ring

- membrane

- smaller ring

- polycarbonate with 15/36” hole

- outer “ring”

- cathode chamber

- design:

- water tight test:

- passed water tight test

- membrane still warps

- water tight test:

- made 1L of LML medium (for anaerobic Shewie growth) ( see recipe here)

- pH was 3.5 initially

- added NaOH until pH at 6.99

- autoclaved

Friday: June 27, 2008

Lab

- Finished building air cathode MFC, minus injection ports

- Autoclaved LML

Keithley test

- Connected simple battery-resistor circuit to both 2700 alone and with 7700 switching module

- Used 8.78 V source of 4M ohm resistance with 1% accuracy

- Calculated current = 2.19 microamps

- Measured current (from 2700) = 2.5 microamps

- Measured current (from 7700) = 2.8 microamps

- Used 8.78 V source of 4M ohm resistance with 1% accuracy

MFC test

1k ohms resistance

- Bubbled nitrogen and oxygen into anode/cathode chambers.

- 60mL LML medium and 15mL distilled water in anode chamber

- 40mL of LML and 35mL distilled water in cathode chamber

- Current began at around 21 microamperes, dropped fairly consistently before plateauing around 10 microamps after 50 minutes

- Added small amounts of lactate, HEPE buffer, yeast extract, peptone in attempt to cancel out the current

- saw sudden rise in current, but then decreased again.

- no notable difference thereafter.

Switched to 10k resistance

- dropped to about 4 microamps

- very very very slow increase (about 4.1-4.3 microamps in 10 minutes)

Added shewie

- initial increase to about 5.25 microamps

- slow and steady increase to about 6.7 microamps

Switched back to 1k resistance

- shot up to about 21 microamps

- decreased to about 13.5 microamps after 10 minutes

Questions to answer

- What temperature were the fuel cells kept at? Do they need to be incubated at 30ºC?

- What type of shewie is ideal for anaerobic current production? How long should they have grown in liquid culture?

- What concentration of shewie should be added per 50 mL of medium? OD?

- How much current should be produced over 2 minute increments? Current production over time pattern.

- How much resistance should we be using?

- What should the voltage difference be? 6 volts?

- What is the best medium? Can we get away with our LML medium, or will we need to make the....extensive recipe?

- Why is there current production without shewie? Distilled water test?

"

"