Team:Valencia/Project/Lab work

From 2008.igem.org

| (4 intermediate revisions not shown) | |||

| Line 12: | Line 12: | ||

| | | | ||

<h3>Materials</h3> | <h3>Materials</h3> | ||

| - | To build | + | To build your own LCC you need the following materials: |

*A commercial thermo flask | *A commercial thermo flask | ||

*Armaflex© | *Armaflex© | ||

*Thermocouple | *Thermocouple | ||

| - | *Acquisition and storing | + | *Acquisition and storing systems, for instance, a dataloguer with a temperature card and a RS-232 cable. |

*A computer | *A computer | ||

| Line 27: | Line 27: | ||

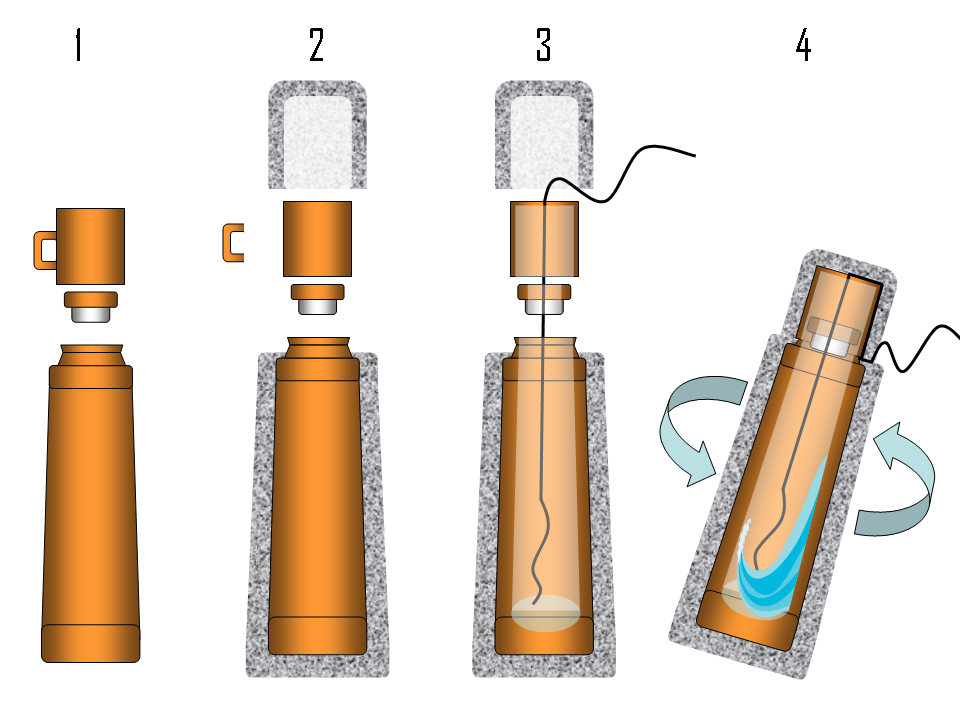

Building your own calorimeter system is easy. You just need to follow the next steps: | Building your own calorimeter system is easy. You just need to follow the next steps: | ||

{| | {| | ||

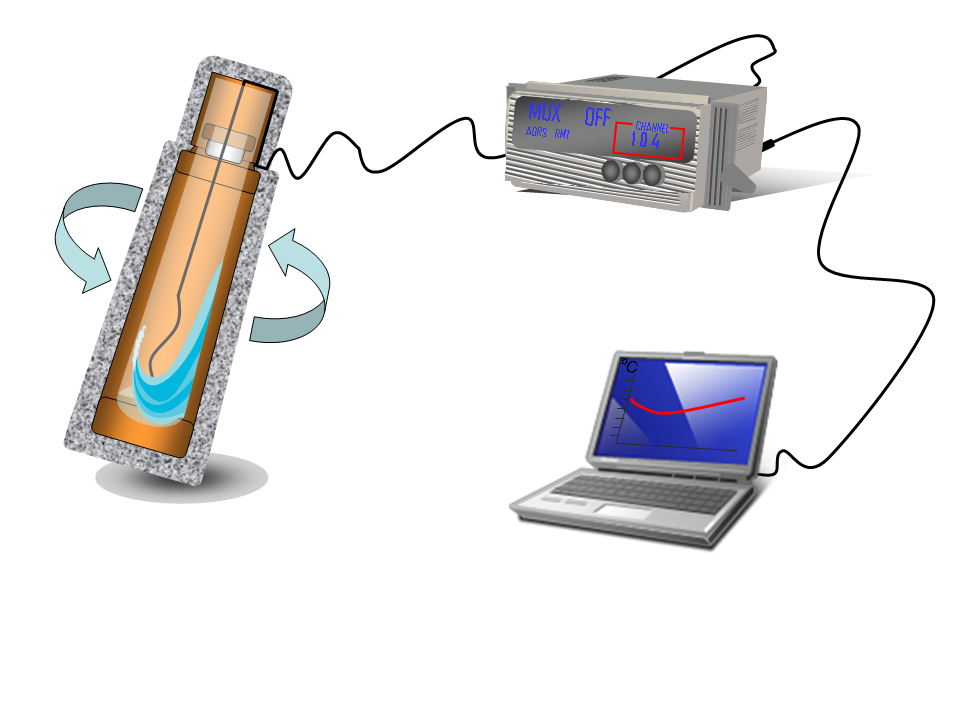

| - | |<ol><li>Select the measurement device, in our case a type T thermocouple(Cu-constantan). | + | |<ol><li>Select the measurement device, in our case a type T thermocouple (Cu-constantan). |

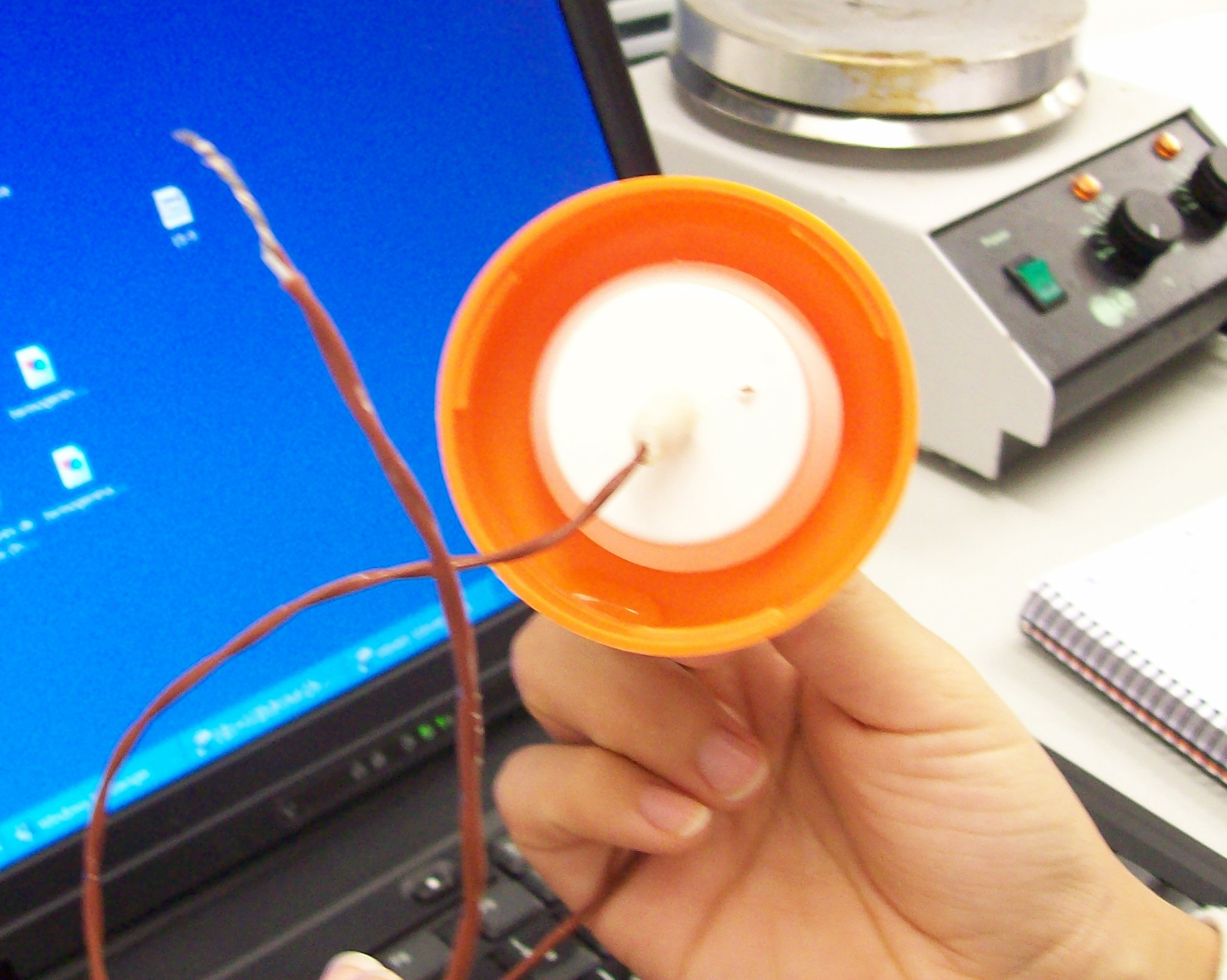

| - | </li><li>Build the thermocouples. It is very easy!! You just peel both cables then join them and you obtain a | + | </li><li>Build the thermocouples. It is very easy!! You just peel both cables and then join them and you will obtain a high precision thermometer. To record the temperature measurements of the thermocouples, they were connected to a voltage acquisition card inserted on a data logger. |

| - | </li><li>Go to a calibration bath and calibrate the thermocouples according to a standard | + | </li><li>Go to a calibration bath and calibrate the thermocouples according to a standard thermoresistance. The precision of the system was up to 0.01 K degrees! |

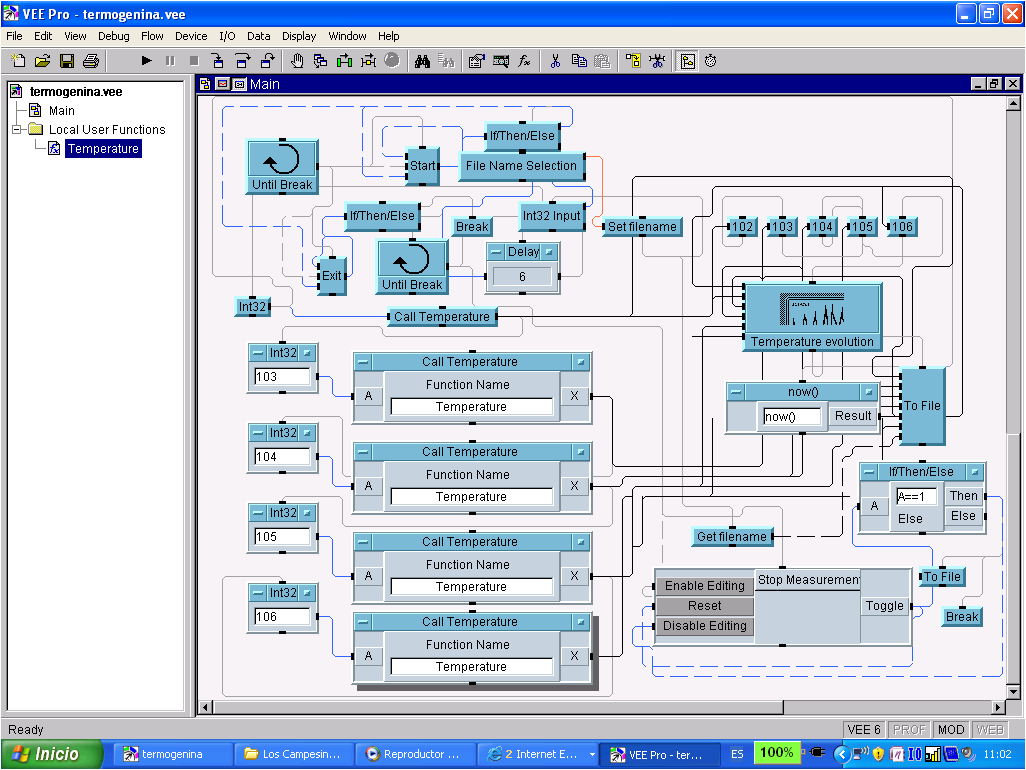

| - | </li><li> | + | </li><li>Develop an acquisition program. Vee pro was used to developed a program that allows communication between the data logger and the computer (a RS-232 cable was used). Through this program, we can select the measurements frequency and store the temperature readings in the computer. We can also record the temperature evolution during the experiments in real time. |

| - | </li><li>Take a commercial plastic and glass thermo flask (in our case we | + | </li><li>Take a commercial plastic and glass thermo flask (in our case we used four) and proceed to the following modifications: |

| - | • Cut off the handle and | + | • Cut off the handle and drill a hole in the cap. Then, insert the thermocouple through the hole. |

| - | • Cover the thermo flask with insulation foam | + | • Cover the thermo flask with insulation foam (Armaflex©) in order to improve thermal isolation. |

• Introduce a garbage bag between the flask and the Armaflex© in order to prevent this material from getting wet. Find out more in the [[Team:Valencia/Project/Lab_work#Troubleshooting | Troubleshooting]] section. | • Introduce a garbage bag between the flask and the Armaflex© in order to prevent this material from getting wet. Find out more in the [[Team:Valencia/Project/Lab_work#Troubleshooting | Troubleshooting]] section. | ||

| Line 55: | Line 55: | ||

<h3>Characterization results</h3> | <h3>Characterization results</h3> | ||

<br> | <br> | ||

| - | After trying different combinations of | + | After trying different combinations of shaking speed, flask tilt and culture volume, we obtained a combination of conditions suitable for the experiment (allowing optimal respiration of yeast culture): 270 rpm, approximately 10 º tilt and 100 ml in a 1L flask, with the thermocouple measuring submerged in the liquid. |

| - | In | + | In these conditions, the 4 LCCs were characterized with water at the temperature of the future experiments, in order to establish the range of heat losses to the environment of the system. The results are shown in the following figures: |

[[Image:UCP_graf_termos.jpg|500px|center]] | [[Image:UCP_graf_termos.jpg|500px|center]] | ||

| Line 68: | Line 68: | ||

<br> | <br> | ||

| - | We have encountered some adversities regarding Armaflex©. This material is sensitive to mechanical damage and especially to water. No matter how careful we were, we found the insulation capacity of our system had drastically decreased | + | We have encountered some adversities regarding Armaflex©. This material is sensitive to mechanical damage and especially to water. No matter how careful we were, we found the insulation capacity of our system had drastically decreased after a few weeks. |

<br> | <br> | ||

| Line 75: | Line 75: | ||

|The main problem was cleaning the LCCs, since it was very difficult for them not to get wet. We tried different protocols, such as covering them with aluminum foil and sealing with parafilm or using funnels, but the water got inside anyway. Every time the temperatures were falling more than usual, we had to stop the experiment, remove Armaflex© cover and use a hair dryer to dry it. | |The main problem was cleaning the LCCs, since it was very difficult for them not to get wet. We tried different protocols, such as covering them with aluminum foil and sealing with parafilm or using funnels, but the water got inside anyway. Every time the temperatures were falling more than usual, we had to stop the experiment, remove Armaflex© cover and use a hair dryer to dry it. | ||

<br> | <br> | ||

| - | Covering the outside was not enough; we needed something that covered the | + | Covering the outside was not enough; we needed something that covered the inner part of the Armaflex©, between the flask and the Armaflex©. We used a garbage bag to do this, and surprisingly, it has worked up to now. |

|} | |} | ||

<br> | <br> | ||

{| | {| | ||

| - | |With regard to the LCCs characterization, we have also gone through different conditions | + | |With regard to the LCCs characterization, we have also gone through different conditions. The first problem we encountered was the apparition of sudden periodic oscillations of temperature in some of the experiments. The best explanation was that water was somehow coming in contact with the thermocouple, which was placed in the upper part of the flask at that time. To try and solve that, we reduced the liquid volume, but the problem persisted. After checking that this phenomenon was not produced when the shaking was stopped, it became clear the oscillations were related to it, probably because of a condensation process. |

|[[Image:Valencia_LCC3.JPG|141px|right]] | |[[Image:Valencia_LCC3.JPG|141px|right]] | ||

|[[Image:Valencia_LCC2.JPG|250px|right]] | |[[Image:Valencia_LCC2.JPG|250px|right]] | ||

| Line 87: | Line 87: | ||

<br> | <br> | ||

| - | Another condition we changed was the position of the thermocouple inside the flask. They had been always placed in the upper part, having no contact with the liquid because of contamination reasons. However, our engineer team members suggested it would be better for the thermocouples to be submerged in the liquid. After carrying out an experiment, we saw there was not | + | Another condition we changed was the position of the thermocouple inside the flask. They had been always placed in the upper part, having no contact with the liquid because of contamination reasons. However, our engineer team members suggested it would be better for the thermocouples to be submerged in the liquid. After carrying out an experiment, we saw there was not significant difference between both positions and none of them resulted in contamination either. Since the data obtained is more exact with the thermocouple submerged, we decided to keep them that way. |

| Line 98: | Line 98: | ||

<div style="padding: 10px; width: 500px; color: #000000; background-color: #FFB428"> | <div style="padding: 10px; width: 500px; color: #000000; background-color: #FFB428"> | ||

| - | <center><font face="trebuchet ms" style="color:#047DB5" size="3"> [[Team:Valencia/Project/Objectives | <font color="#047DB5">'''Objectives'''</font>]] << '''LCC Construction ''' >> [[Team:Valencia/Project/Lab_work/2_experiments | <font color="#047DB5">'''Hot Yeast Experiments'''</font>]]</font> | + | <center><font face="trebuchet ms" style="color:#047DB5" size="3"> [[Team:Valencia/Project/Objectives | <font color="#047DB5">'''Objectives'''</font>]] << '''1.LCC Construction ''' >> [[Team:Valencia/Project/Lab_work/2_experiments | <font color="#047DB5">'''2.Hot Yeast Experiments'''</font>]]</font> |

</center> | </center> | ||

</div style> | </div style> | ||

Latest revision as of 00:23, 30 October 2008

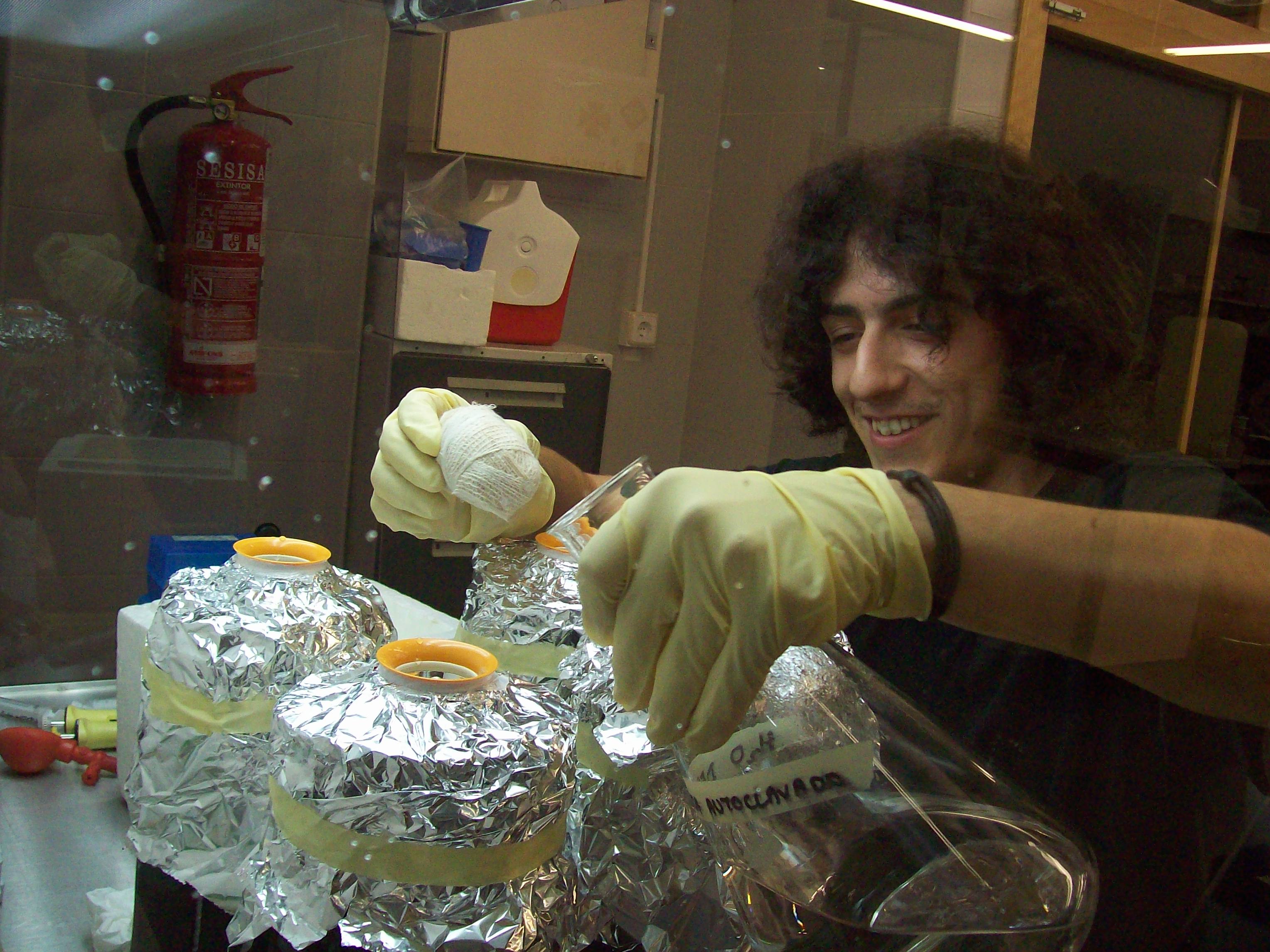

1.- Construction of a Liquid Culture Calorimeter (LCC).

MaterialsTo build your own LCC you need the following materials:

|

Method

Building your own calorimeter system is easy. You just need to follow the next steps:

|

|

|

Characterization results

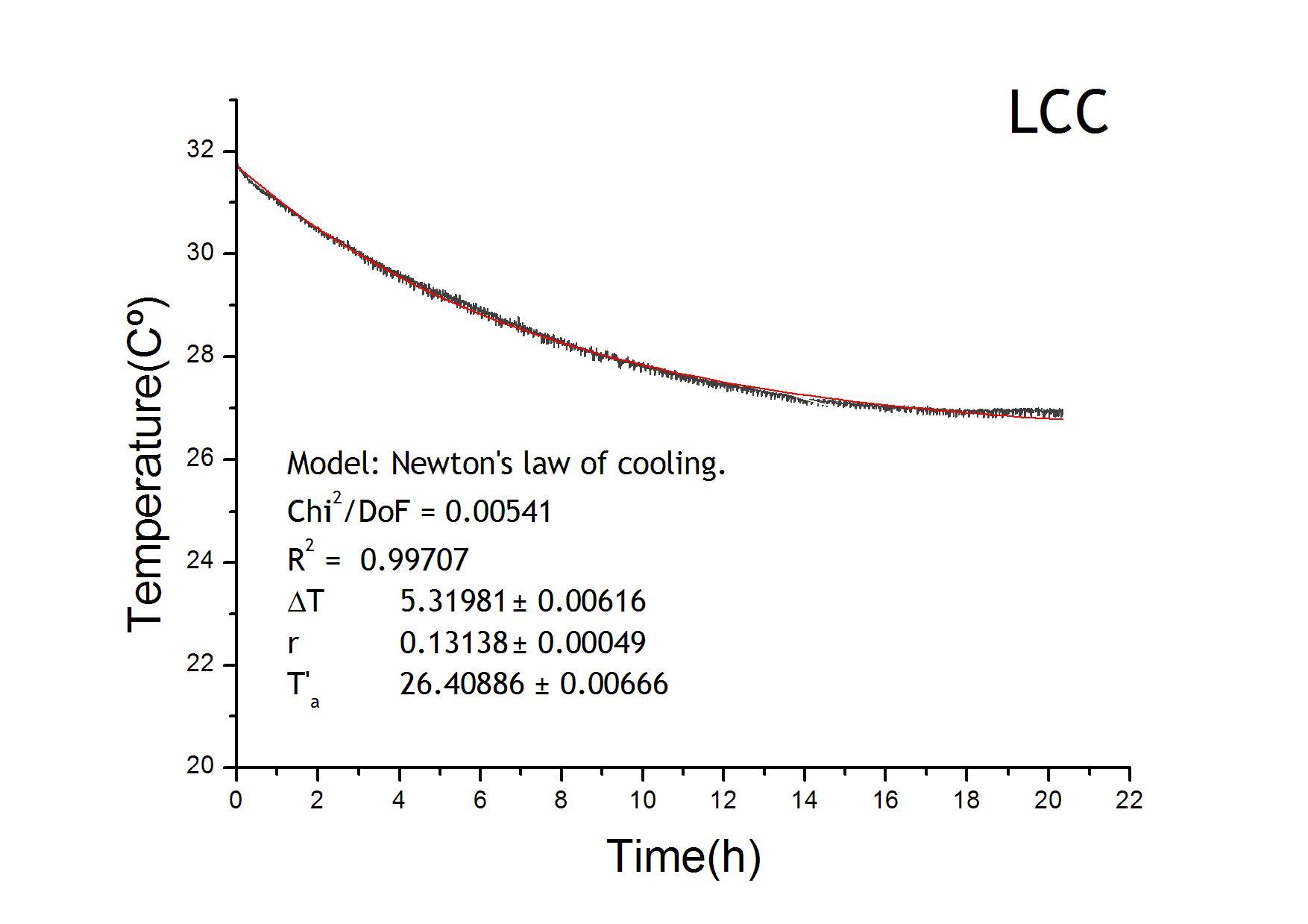

After trying different combinations of shaking speed, flask tilt and culture volume, we obtained a combination of conditions suitable for the experiment (allowing optimal respiration of yeast culture): 270 rpm, approximately 10 º tilt and 100 ml in a 1L flask, with the thermocouple measuring submerged in the liquid.

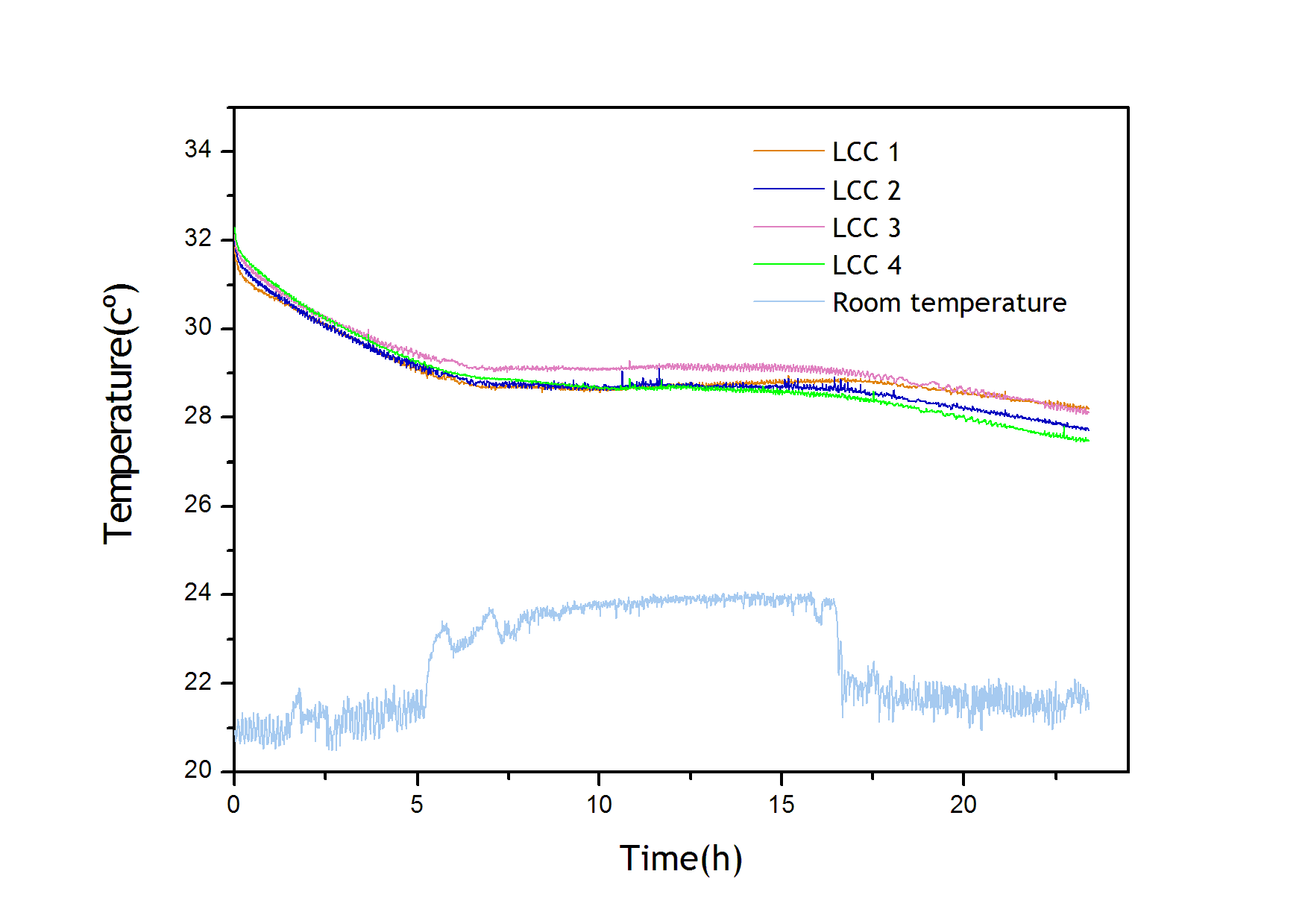

In these conditions, the 4 LCCs were characterized with water at the temperature of the future experiments, in order to establish the range of heat losses to the environment of the system. The results are shown in the following figures:

To show how room temperature can affect temperature inside the LCCs, we repeated the experiment producing a variation in room temperature. The result was:

Troubleshooting

We have encountered some adversities regarding Armaflex©. This material is sensitive to mechanical damage and especially to water. No matter how careful we were, we found the insulation capacity of our system had drastically decreased after a few weeks.

| The main problem was cleaning the LCCs, since it was very difficult for them not to get wet. We tried different protocols, such as covering them with aluminum foil and sealing with parafilm or using funnels, but the water got inside anyway. Every time the temperatures were falling more than usual, we had to stop the experiment, remove Armaflex© cover and use a hair dryer to dry it.

|

| With regard to the LCCs characterization, we have also gone through different conditions. The first problem we encountered was the apparition of sudden periodic oscillations of temperature in some of the experiments. The best explanation was that water was somehow coming in contact with the thermocouple, which was placed in the upper part of the flask at that time. To try and solve that, we reduced the liquid volume, but the problem persisted. After checking that this phenomenon was not produced when the shaking was stopped, it became clear the oscillations were related to it, probably because of a condensation process. |

The solution to this problem appeared, as usual, when we were not looking for it. In order to provide more oxygen to the culture, we increased the shaking speed and the flask tilt in an experiment with water. Surprisingly, the periodic oscillations disappeared and the temperature not only did not fall so much, but slightly increased. We found we could regulate the temperature with these two factors; therefore, we adjusted them so as to obtain almost stable temperature with a high shaking speed suitable for culture growth.

Another condition we changed was the position of the thermocouple inside the flask. They had been always placed in the upper part, having no contact with the liquid because of contamination reasons. However, our engineer team members suggested it would be better for the thermocouples to be submerged in the liquid. After carrying out an experiment, we saw there was not significant difference between both positions and none of them resulted in contamination either. Since the data obtained is more exact with the thermocouple submerged, we decided to keep them that way.

"

"