Team:MIT

From 2008.igem.org

(→Lactobacillus Work) |

(→Lactobacillus Work) |

||

| Line 53: | Line 53: | ||

We are currently working on a method to effectively miniprep plasmid DNA from our ''Lactobacillus''. For information about our protocol for doing so, please click [http://openwetware.org/wiki/Lactobacillus_miniprep '''here''']. | We are currently working on a method to effectively miniprep plasmid DNA from our ''Lactobacillus''. For information about our protocol for doing so, please click [http://openwetware.org/wiki/Lactobacillus_miniprep '''here''']. | ||

| - | We have built an expression system for Lactobacillus to secrete protein, including individual biobricked parts of a Lactobacillus [http://partsregistry.org/wiki/index.php?title=Part:BBa_K128006 '''promoter'''] and a Lactobacillus http://partsregistry.org/Part:BBa_K128004 '''signal sequence''']. | + | We have built an expression system for Lactobacillus to secrete protein, including individual biobricked parts of a Lactobacillus [http://partsregistry.org/wiki/index.php?title=Part:BBa_K128006 '''promoter'''] and a Lactobacillus [http://partsregistry.org/Part:BBa_K128004 '''signal sequence''']. |

==Acknowledgements== | ==Acknowledgements== | ||

Revision as of 03:57, 30 October 2008

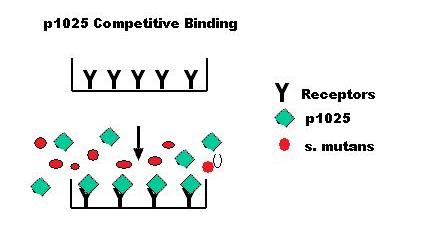

Biogurt: A Sustainable and Savory Drug Delivery SystemStreptococcus mutans, the main cause of dental caries, binds to glycoproteins on the teeth. A clinical study (Kelly CG et al.; Nature Biotechnol. 1999) isolated the 20aa functional segment (p1025) that S.mutans uses to attach to the teeth. p1025 competitively inhibits the binding of S.mutans, causing unharmful bacteria to grow in its place, preventing the recolonization of S.mutans for 90 days. We are engineering Lactobacillus bulgaricus, a bacteria commonly found in yogurt, to produce and secrete this peptide under a promoter activated by lactose. The peptide p1025 could simply be added to any food. But production of this peptide by L. bulgaricus is an independent process, so inserting the gene into live bacteria in yogurt will enable continuous production. Since a new batch of yogurt can be made using the bacteria from a small amount of the old batch, a continuous supply of teeth-cleaning yogurt will be available from the first successfully engineered batch. This could be the key to providing effective dental health care in underdeveloped rural communities, especially if yogurt is already an integral part of the diet. Also, the p1025 gene could be replaced by any other gene, so this same expression system could be used to produce other useful peptides. Yogurt with modified bacteria will provide a cheap, efficient, and delicious way to distribute vitamins, vaccines and more. ResultsCharacterization

Models

New Methods

Lactobacillus WorkWe successfully transformed Lactobacillus delbruckii subsp. bulgaricus and Lactobacillus delbruckii subsp. lactis with a modified version of Serror et al's electrotransformation procedure. Our [http://openwetware.org/wiki/Lactobacillus_transformation transformation protocols] are found here. We also plan to submit these plasmids, with biobrick sites inserted in them, to the registry. These plasmids are [http://partsregistry.org/wiki/index.php?title=Part:BBa_K128008 pJK650] and [http://partsregistry.org/wiki/index.php?title=Part:BBa_K128007 pLEM415]. We are currently working on a method to effectively miniprep plasmid DNA from our Lactobacillus. For information about our protocol for doing so, please click [http://openwetware.org/wiki/Lactobacillus_miniprep here]. We have built an expression system for Lactobacillus to secrete protein, including individual biobricked parts of a Lactobacillus [http://partsregistry.org/wiki/index.php?title=Part:BBa_K128006 promoter] and a Lactobacillus [http://partsregistry.org/Part:BBa_K128004 signal sequence]. AcknowledgementsGraduate AdvisersScott Carlson, Felix Moser, Chia-Yung Wu, Lav Varshney, Vikramaditya Yadav, Woo Chung, Rachel Hilmer, Robbier Barbero, Brian Cook, Jyoti Goda, Laure-Anne Ventouras Faculty Advisors:Drew Endy, Tom Knight OthersIsadora Deese, Dr. Pascale Serror at L'Institut National de la Recherche Agronomique, Dr. Bernhard Heinrich at the University of Kaiserslautern, Dr. Chris French at the University of Edinburgh, Dr. Daniel Smith at the Forsyth Institute, Joey Davis at the Sauer Lab at MIT, The Fink Lab at the Whitehead Institute, Emiko Bare at the Keating Lab at MIT, Jennifer Hou at the Baker Lab at MIT, The UROP office and Biological Engineering Department for financial support | ||||||||

|

| ||||||||

| Home | The Team | The Project | Experiments | Parts Submitted to the Registry | Modeling | Notebook |

|---|

"

"