Team:Harvard/Hardware

From 2008.igem.org

(→Background) |

(→Software) |

||

| (5 intermediate revisions not shown) | |||

| Line 58: | Line 58: | ||

==Motivation== | ==Motivation== | ||

| - | The broad goal of our project was to engineer | + | The broad goal of our project was to engineer ''S. Oneidensis'' to produce a detectable change in electric current in response to some environmental stimulus. In order to observe such a reaction, our first task was to design an environment capable of housing bacteria and measuring current production. |

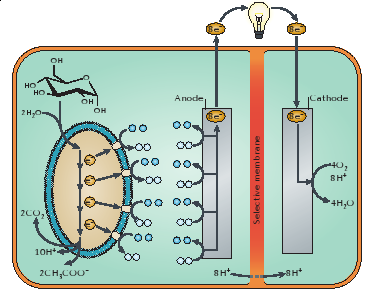

==Solution - Microbial Fuel Cells== | ==Solution - Microbial Fuel Cells== | ||

| Line 93: | Line 93: | ||

* anaerobic/aerobic | * anaerobic/aerobic | ||

| - | + | S. oneidensis MR-1 only oxidizes substrates in anaerobic environments. The chambers housing the bacteria must be oxygen free and airtight. | |

* sterile | * sterile | ||

| Line 102: | Line 102: | ||

* accessible | * accessible | ||

| - | Experimenters must have access to the bacterial environment. | + | Experimenters must have access to the bacterial environment. |

| - | + | ||

==Approach== | ==Approach== | ||

| Line 119: | Line 118: | ||

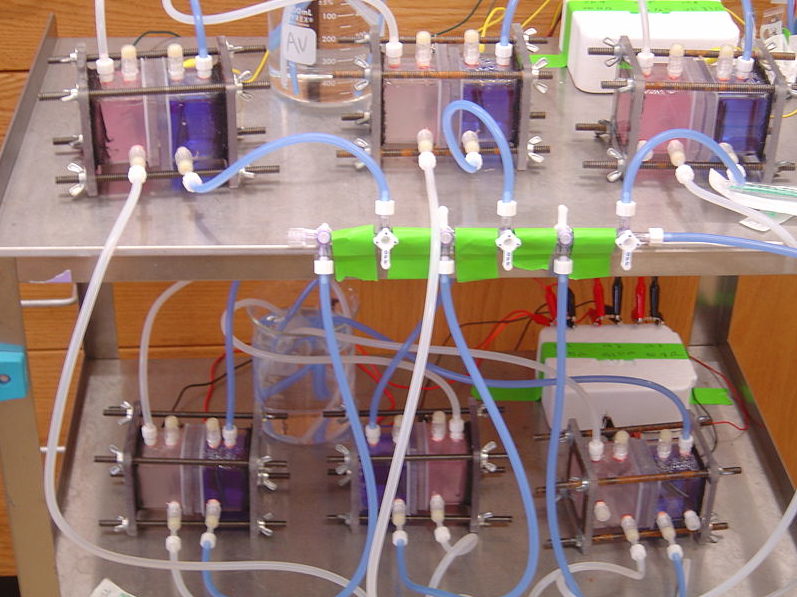

The simple picture of our design was a hollow tube, sealed at both ends with endplates, and cut in half horizontally to allow for insertion of a semi-permeable membrane. The two halves would then be clamped back together to close the system. Ports needed to be drilled into the walls of the tube to allow for insertion of the anode and cathode, as well as to initially fill the sealed chambers with media and inject bacteria and food. Previous research suggested bubbling gasses into the chambers could improve performance. In the anode chamber, nitrogen was typically bubbled to purge the chamber of oxygen, keeping the bacteria in a controlled anaerobic environment. In the cathode chamber, air was typically bubbled to provide a continuous source of oxygen, ensuring an efficient reduction reaction. We decided to include ports for gas inlet and outlet as well. | The simple picture of our design was a hollow tube, sealed at both ends with endplates, and cut in half horizontally to allow for insertion of a semi-permeable membrane. The two halves would then be clamped back together to close the system. Ports needed to be drilled into the walls of the tube to allow for insertion of the anode and cathode, as well as to initially fill the sealed chambers with media and inject bacteria and food. Previous research suggested bubbling gasses into the chambers could improve performance. In the anode chamber, nitrogen was typically bubbled to purge the chamber of oxygen, keeping the bacteria in a controlled anaerobic environment. In the cathode chamber, air was typically bubbled to provide a continuous source of oxygen, ensuring an efficient reduction reaction. We decided to include ports for gas inlet and outlet as well. | ||

| - | Materials for the chamber were then selected. The central tube and endplates were made from polycarbonate. This is a clear, hard plastic that is easily bonded to itself with silicone glue. It has the added benefit of allowing visual monitoring of the chambers, it is easily milled, and it can be autoclaved. Silicone was used in glue form to bond the tubes to their endplates, and it was used in solidified from to construct gaskets which sealed the two chambers together when clamped. The clamping mechanism involved drilling holes through the overlap of the endplates, inserting iron threaded rods down the length of the chambers, and fastening the ends of the rods with wing nuts. | + | Materials for the chamber were then selected. The central tube and endplates were made from polycarbonate. This is a clear, hard plastic that is easily bonded to itself with silicone glue. It has the added benefit of allowing visual monitoring of the chambers, it is easily milled, and it can be autoclaved. Silicone was used in glue form to bond the tubes to their endplates, and it was used in solidified from to construct gaskets which sealed the two chambers together when clamped. The clamping mechanism involved drilling holes through the overlap of the endplates, inserting iron threaded rods down the length of the chambers, and fastening the ends of the rods with wing nuts. |

| + | |||

| + | The anode material was chosen to provide maximal surface area and attachment sites for bacteria. Carbon felt provided such a surface. | ||

| + | |||

| + | The cathode material needed to provide an efficient surface for the reduction reactions to take place. Platinum on carbon cloth acted as a catalyst for this reaction. | ||

| + | |||

| + | Titanium wire was used to connect the cathode and anode surfaces to an external resistor as it cannot be oxidized, which would interfere with the reactions. | ||

====Measurement==== | ====Measurement==== | ||

| Line 136: | Line 141: | ||

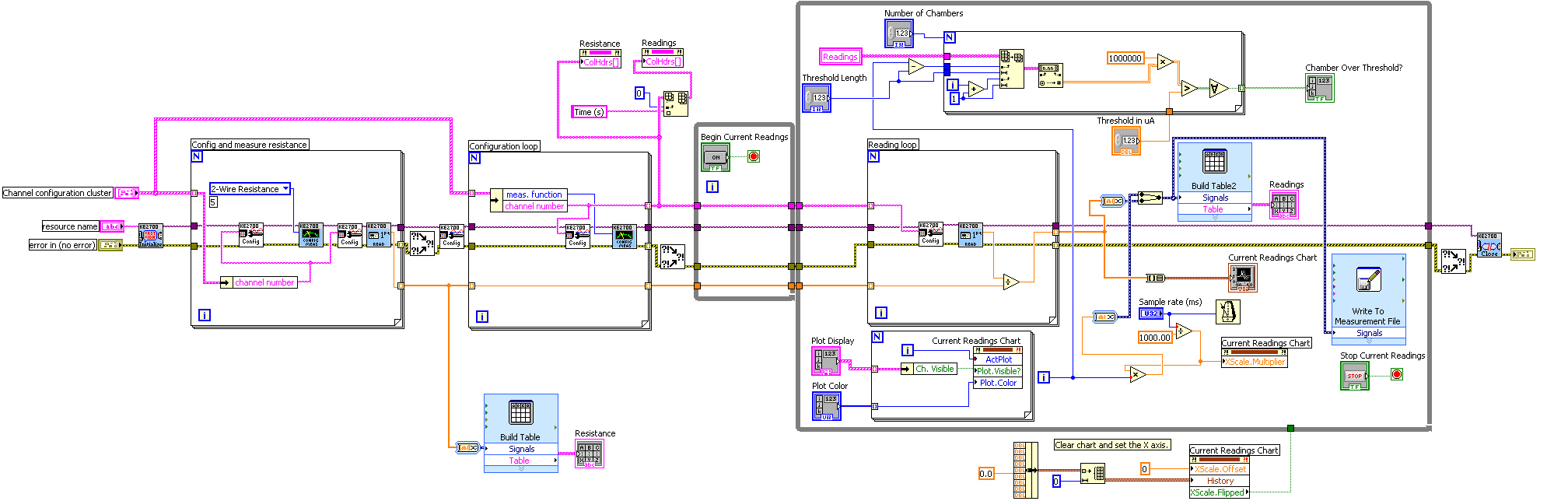

* In LabVIEW, a block diagram is used to visually write c code. Our block diagram is shown here. | * In LabVIEW, a block diagram is used to visually write c code. Our block diagram is shown here. | ||

| - | [[Image: | + | [[Image:Labview.jpg|600px]] |

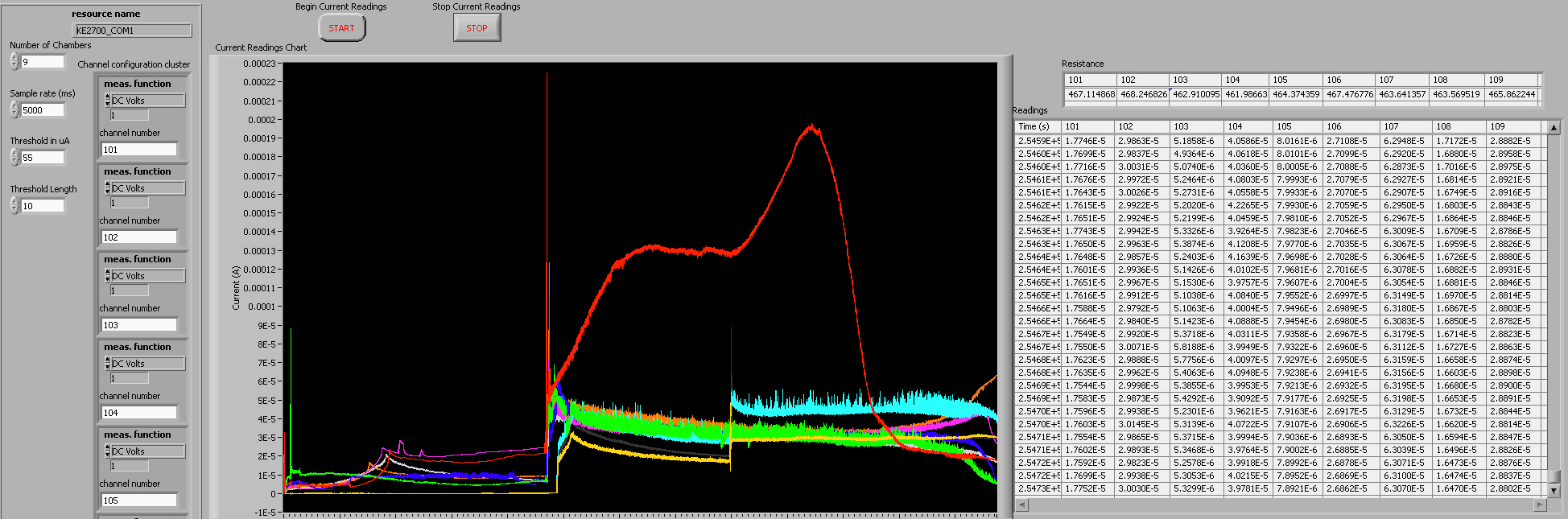

* In Labview, an instrument panel is used to allow users to specify inputs and to display the status of program variables. Our instrument panel is shown here. | * In Labview, an instrument panel is used to allow users to specify inputs and to display the status of program variables. Our instrument panel is shown here. | ||

| - | [[Image: | + | [[Image:Labview2.jpg|600px]] |

|} | |} | ||

Latest revision as of 04:12, 30 October 2008

|

|

"

"