Team:Valencia/Project/Lab work

From 2008.igem.org

| Line 10: | Line 10: | ||

{| | {| | ||

| | | | ||

| + | <h3>Materials</h3> | ||

| + | *A commercial thermo flask | ||

| + | *Armaflex© | ||

| + | *Thermocouple | ||

| + | *Acquisition and storing system, for instance, a datalogues with a temperature card and a rs-232 cable. | ||

| + | *A computer | ||

| + | |||

| + | <h3>Method</h3> | ||

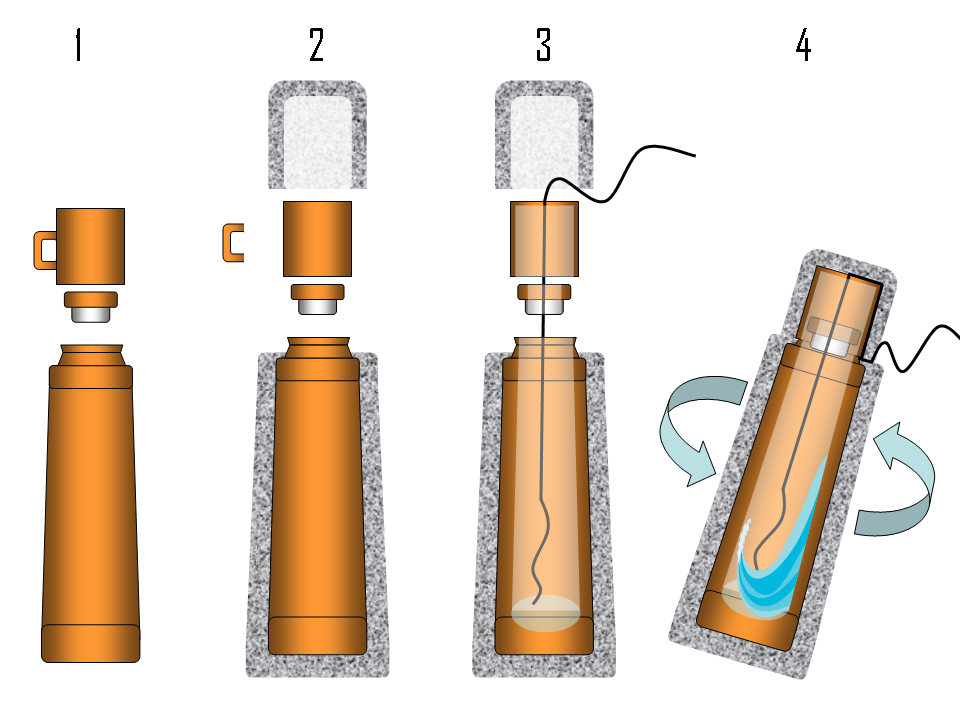

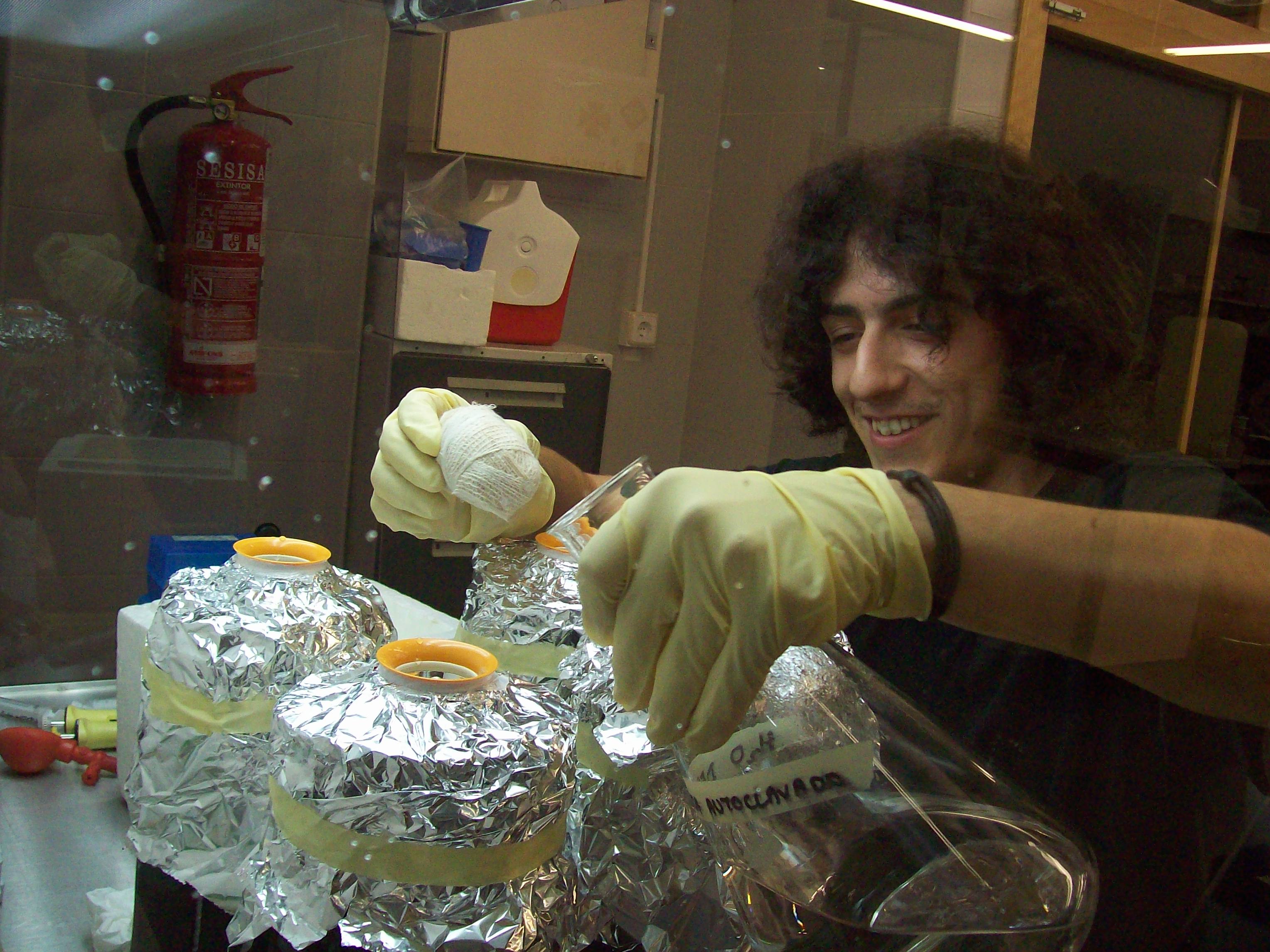

Our LCC consists of four commercial plastic and glass thermo flasks which we modified. We cut off the handle and drilled a hole in the cap. We inserted the thermocouple through the hole and covered the whole calorimeter with insulation foam called Armaflex©. | Our LCC consists of four commercial plastic and glass thermo flasks which we modified. We cut off the handle and drilled a hole in the cap. We inserted the thermocouple through the hole and covered the whole calorimeter with insulation foam called Armaflex©. | ||

| | | | ||

[[Image:Valencia_LCC.png|450 px|right]] | [[Image:Valencia_LCC.png|450 px|right]] | ||

|} | |} | ||

| - | |||

| - | |||

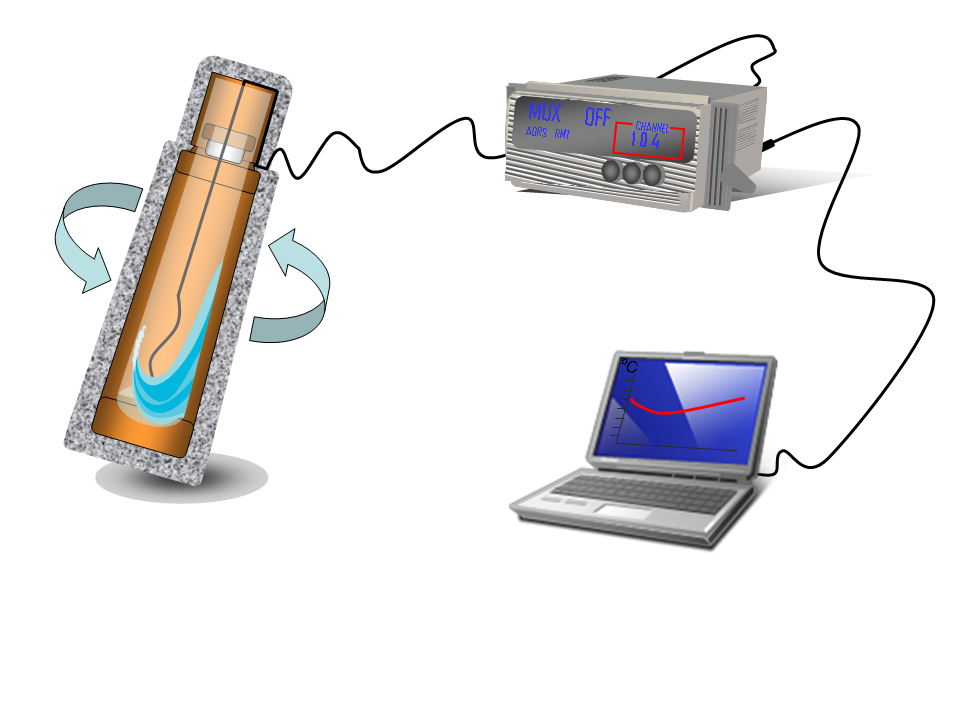

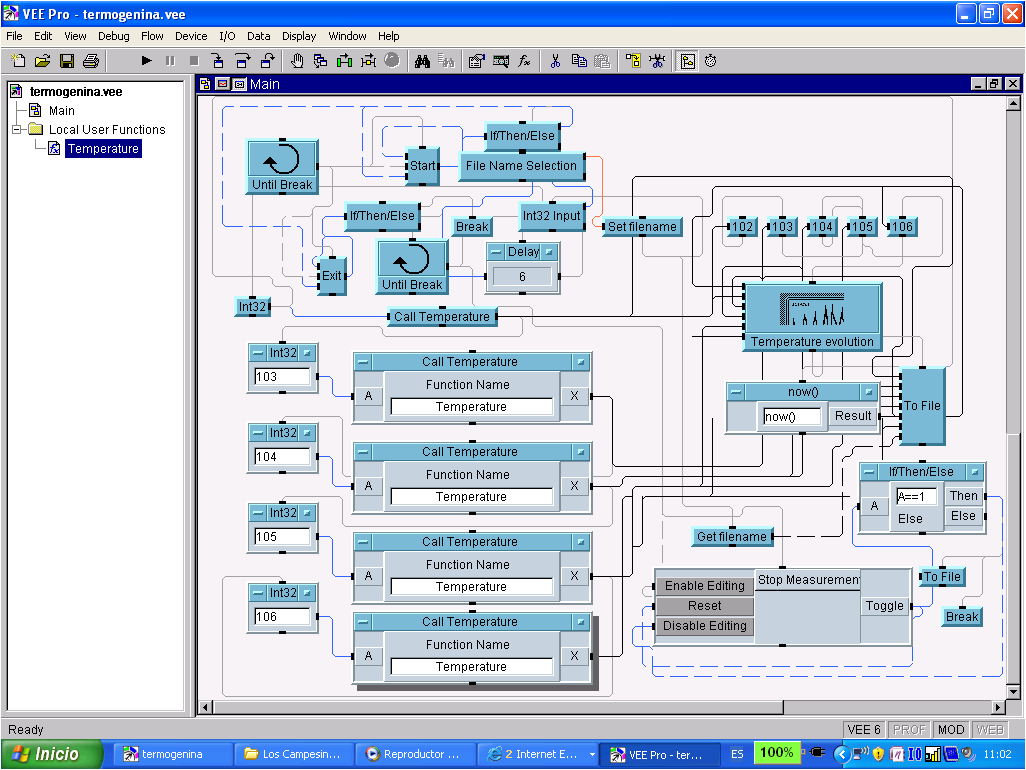

The thermocouples where connected to a data logger that stores temperature evolution during the experiment. At the same time, this data logger was connected to the computer. We developed a program which interprets the data and shows an updated line chart every 30 seconds. | The thermocouples where connected to a data logger that stores temperature evolution during the experiment. At the same time, this data logger was connected to the computer. We developed a program which interprets the data and shows an updated line chart every 30 seconds. | ||

Revision as of 16:13, 1 September 2008

Contents |

1.- Construction of a Liquid Culture Calorimeter (LCC).

Materials

MethodOur LCC consists of four commercial plastic and glass thermo flasks which we modified. We cut off the handle and drilled a hole in the cap. We inserted the thermocouple through the hole and covered the whole calorimeter with insulation foam called Armaflex©. |

The thermocouples where connected to a data logger that stores temperature evolution during the experiment. At the same time, this data logger was connected to the computer. We developed a program which interprets the data and shows an updated line chart every 30 seconds.

|

|

Characterization results

After trying different combinations of revolution speed, flask tilt and liquid volume, we obtained a combination of conditions suitable for the experiment: 250 rpm, approximately 10 º tilt.

Troubleshooting

We have encountered some adversities regarding Armaflex©. This material is sensitive to mechanical damage and especially to water. No matter how careful we were, we found the insulation capacity of our system had drastically decreased in the first weeks.

| The main problem was cleaning the LCCs, since it was very difficult for them not to get wet. We tried different protocols, such as covering them with aluminum foil and sealing with parafilm or using funnels, but the water got inside anyway. Every time the temperatures were falling more than usual, we had to stop the experiment, remove Armaflex© cover and use a hair dryer to dry it.

|

| With regard to the LCCs characterization, we have also gone through different conditions combinations. The first problem we encountered was the apparition of sudden periodic oscillations of temperature in some of the experiments. The best explanation was that water was somehow coming in contact with the thermocouple, which was placed in the upper part of the flask at that time. To try and solve that, we reduced the liquid volume, but the problem persisted. After watching this phenomenon was not produced when the shaking was stopped, it became clear the oscillations were related to it, probably because of a condensation process. |

The solution to this problem appeared, as usual, when we were not looking for it. In order to provide more oxygen to the culture, we increased the shaking speed and the flask tilt in an experiment with water. Surprisingly, the periodic oscillations disappeared and the temperature not only did not fall so much, but slightly increased. We found we could regulate the temperature with these two factors; therefore, we adjusted them so as to obtain almost stable temperature with a high shaking speed suitable for culture growth.

Another condition we changed was the position of the thermocouple inside the flask. They had been always placed in the upper part, having no contact with the liquid because of contamination reasons. However, our engineer team members suggested it would be better for the thermocouples to be submerged in the liquid. After carrying out an experiment, we saw there was not too much different between both positions, but there were not contaminations problems either. Since the data obtained is more exact with the thermocouple submerged, we decided to keep them that way.

"

"