Running an MFC Experiment

This page is intended as a comprehensive guide to completing a microbial fuel cell setup and running an experiment from start to finish.

Creating a Testing Environment

Begin 1-2 weeks prior to experiment

Constructing Fuel Cell Components

Materials (per fuel cell)

- 4" Polycarbonate Square Tube, 2" Outer Diameter

- 6" x 6" Polycarbonate Sheet, 1/4" Thick

- 4 Steel Fully Threaded Stud, 1/4"-20 Thread, 6" Length

- 8 Zinc Alloy Wing Flange Nut, 1/4"-20 Screw Size, 1" Wing Spread

- 1" x 1" Nafion® membrane, 0.180mm thick

- 1" x 1" Carbon felt, 0.25" thick

- 1.5" x 1.5" E-TEK ELAT™ GDE (platinum on carbon)

- 2' Titanium Grade 2 Wire .046" Diameter

- Teflon Tape, 1/4" Width

- 5" x 2.5" Silicone Sheet

- Silicone Glue

- Spiral Point Tap 1/4"-28

- 8 Plastic Luer Lock Coupling Nylon, Female to Male Thread, 1/4"-28

Procedure

- Mill Polycarbonate

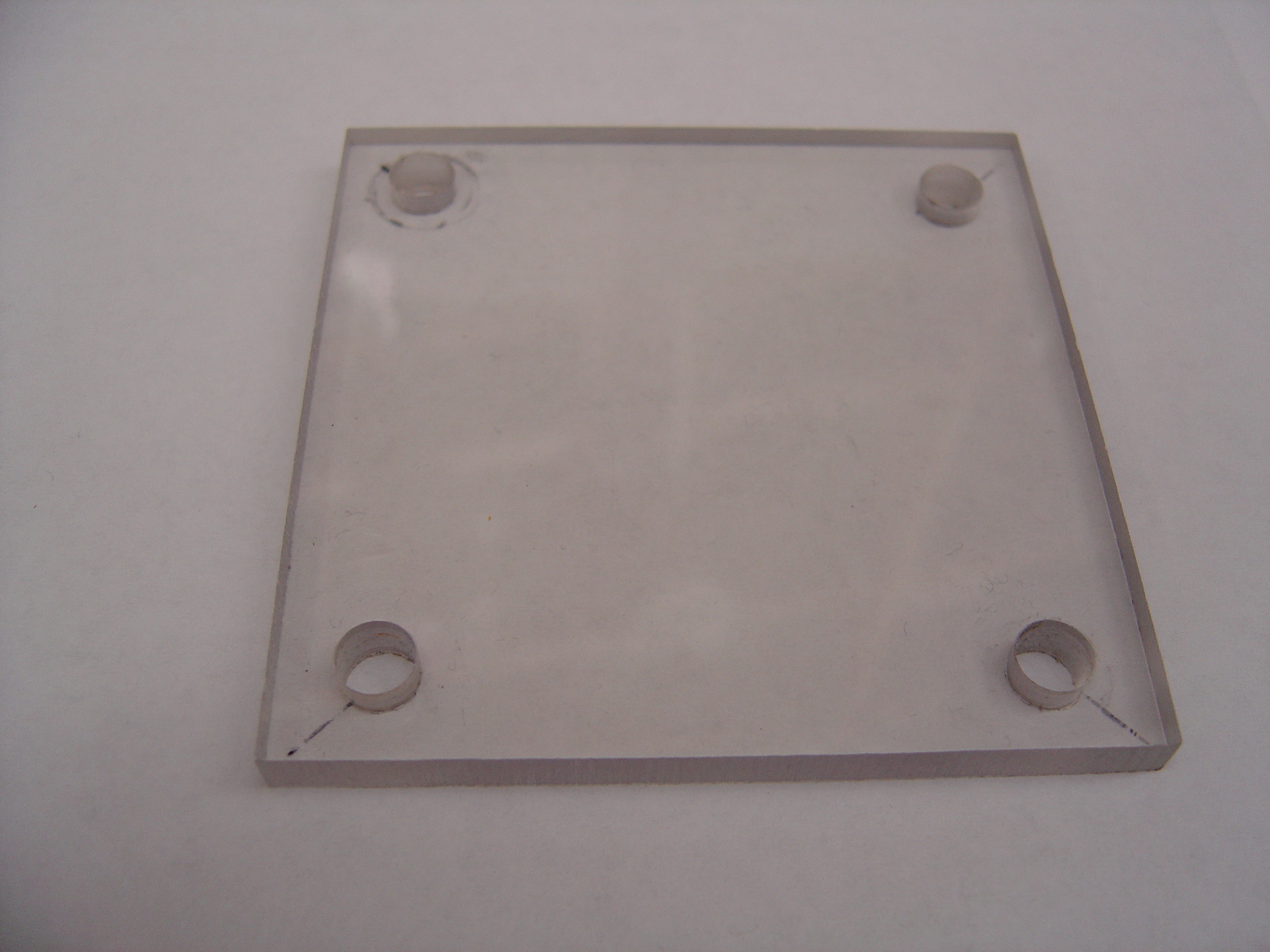

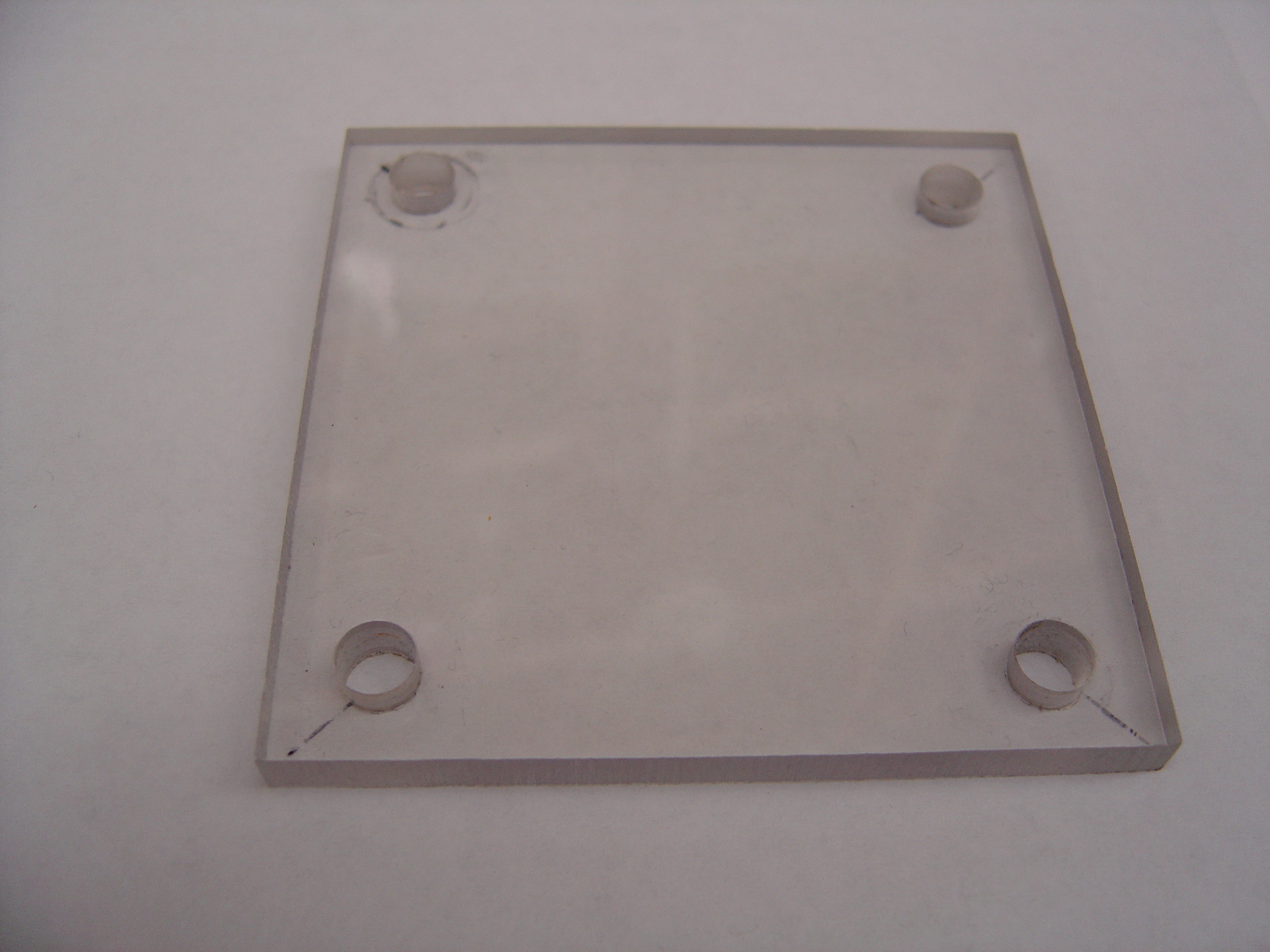

- Cut polycarbonate sheet into 4 equal 3" x 3" pieces

- Drill four 3/8" holes through each piece, 1 per corner, indented 5mm from both sides

- Cut polycarbonate tube into two equal 2" halves

- Drill four 1/4" holes through each half in configuration shown

- Tap each hole with 1/4" -28 spiral tap

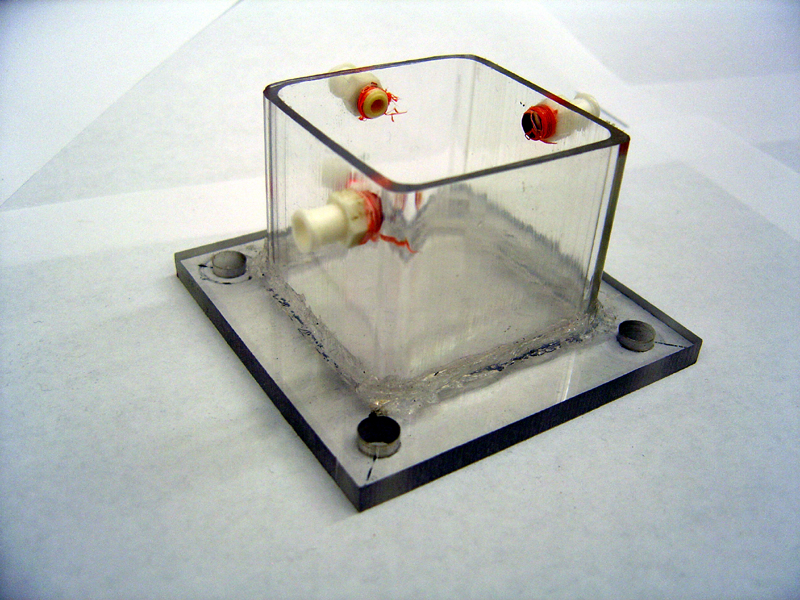

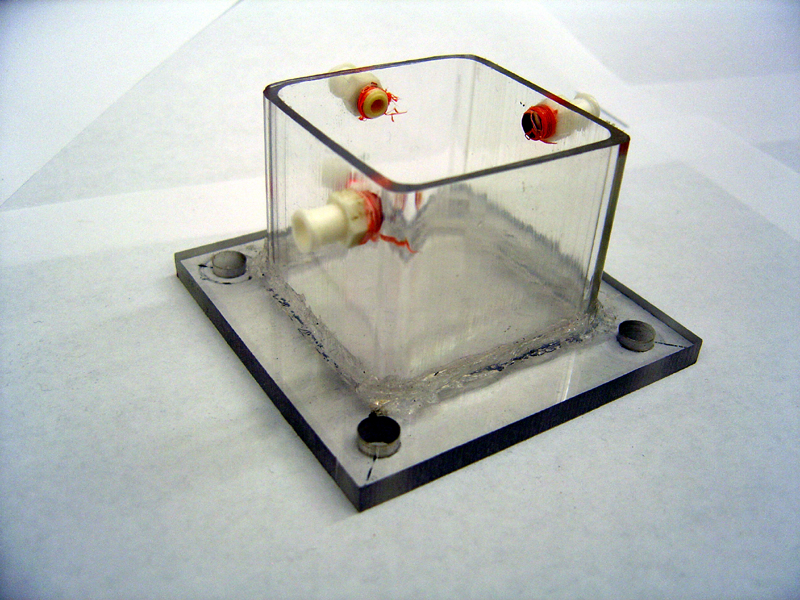

- Glue Chambers (repeat for each half)

- Center tube on endplate by marking plate with 'X' from corner to corner

- Squirt 2mm thick line of silicone on edge of tube (edge furthest from holes)

- Press tube firmly against marked location on endplate

- Quickly spread excess silicone along edge

- Let stand 24h to harden

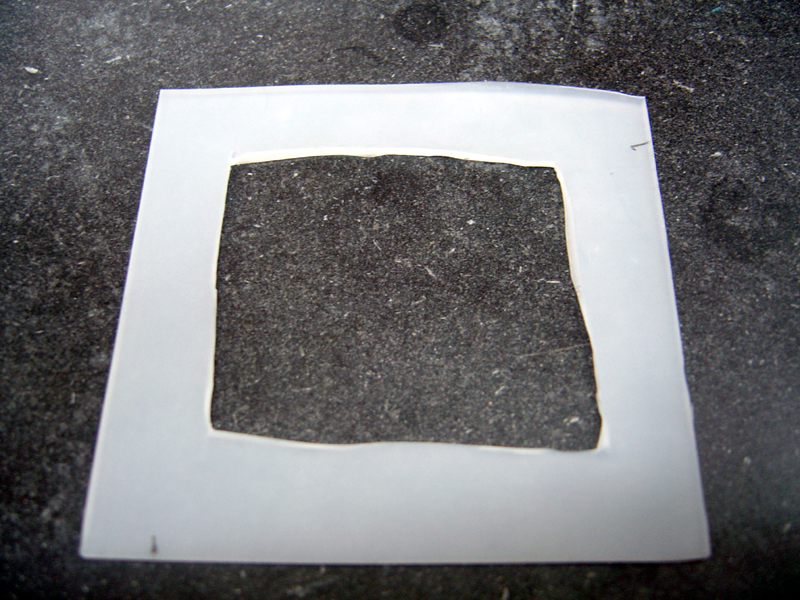

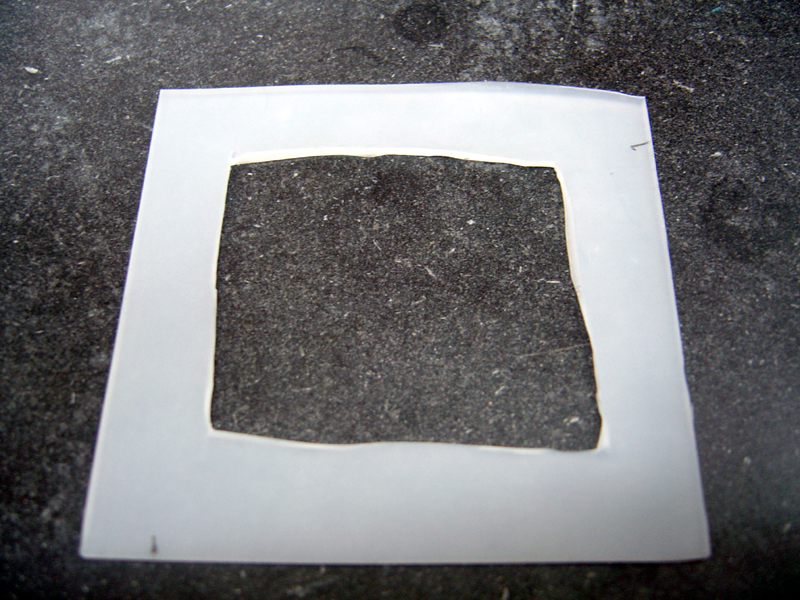

- Construct Gaskets

- Cut silicone sheet into two equal 2.25" x 2.25" pieces

- Cut out centered inner squares in each piece, 1.75" x 1.75"

- Using inner squares, cut two 'O' rings, inner diameter 1/4", outer diameter 1/2"

- Construct Electrodes

- Cut titanium wire into one 8" piece and one 16" piece

- Using pliers, shape anode and cathode as shown

600px

- Spear carbon felt with tip of anode titanium wire and wedge into frame

- Weave platinum carbon cloth through cathode titanium wire

600px

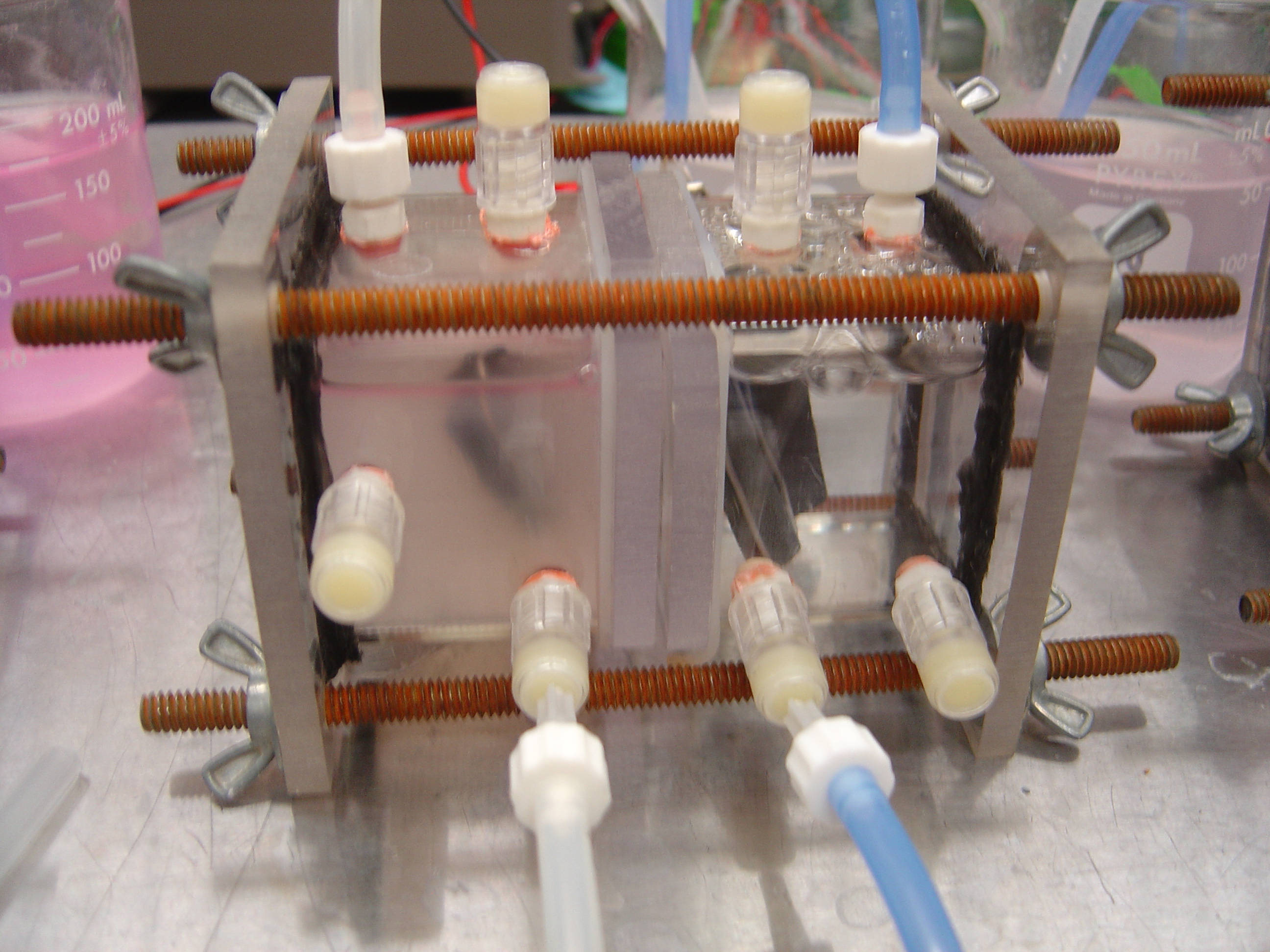

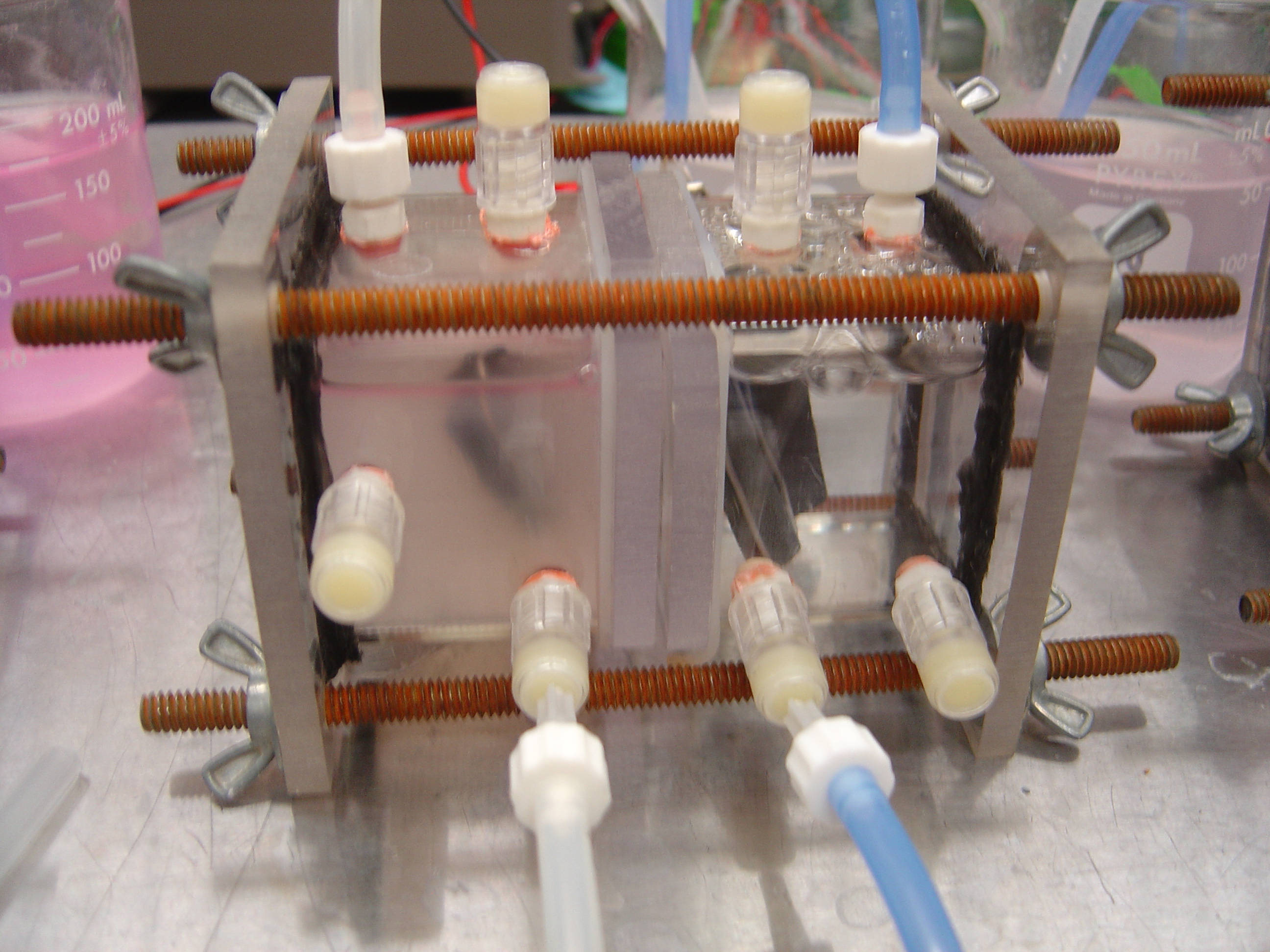

- Seal Injection Ports

- Wrap threads of all eight Luer Lock screws with 1' of teflon tape in opposite direction of screwing

- Screw Luer Locks into all tapped holes in both chambers

Setup of Measurement Device

Materials

- Keithley 2700 Digital Multimeter

- Keithley 7700 Multiplexer

- Small Breadboard

- Supply of insulted thin copper wire

- 470 Ohm resistors (one/fuel cell)

Procedure

- Wire Multiplexer

- Open multiplexer, note channels

- Cut two wire 18" wire leads per fuel cell

- Strip ends, place one wire in each screw terminal, screw tight

- Tape paired wires (two are attached to each channel) near non-attached ends and label

- Clamp wire bundles near back of device with provided plastic latch clamps

- Close Multiplexer and slide into 2700 DMM

- Create Resistor Array

- Connect resistors across middle of breadboard (one per fuel cell)

- Connect leads from multiplexer across resistors (one pair across each resistor)

Controlling the DMM with LabVIEW™

- Initialize Multimeter

- Attach 2700 to COM1 port of desktop computer w/ LabVIEW™

- Download our LabVIEW™ source code MFCs.vi

- Open Program in LabVIEW™,

-

Experiment Preparation

Begin 1 day prior to experiment

Assembling Chambers

Solutions Prep

Chamber media

- 5.844 g/L 100mM NaCl

- 15.1185 g/L 50mM PIPES (hydrogen)

7.0 pH

Phosphate buffer

- 2.918 g/L Monosodium phosphate, monohydrate

- 4.095 g/L Disodium phosphate, anhydrous

- 5.844 g/L 100mM NaCl

7.0 pH

Gas Tubing Assembly

Growing Strains

Runtime

Begin 2 hours prior to experiment

Bacteria

Fuel Cells

Injections/Variables

Clean Up

|

"

"