Running an MFC Experiment

This page is intended as a comprehensive guide to completing a microbial fuel cell setup and running an experiment from start to finish.

Creating a Testing Environment

Begin 1-2 weeks prior to experiment

Constructing Fuel Cell Components

Materials (per fuel cell)

- 4" Polycarbonate Square Tube, 2" Outer Diameter

- 6" x 6" Polycarbonate Sheet, 1/4" Thick

- 4 Steel Fully Threaded Stud, 1/4"-20 Thread, 6" Length

- 8 Zinc Alloy Wing Flange Nut, 1/4"-20 Screw Size, 1" Wing Spread

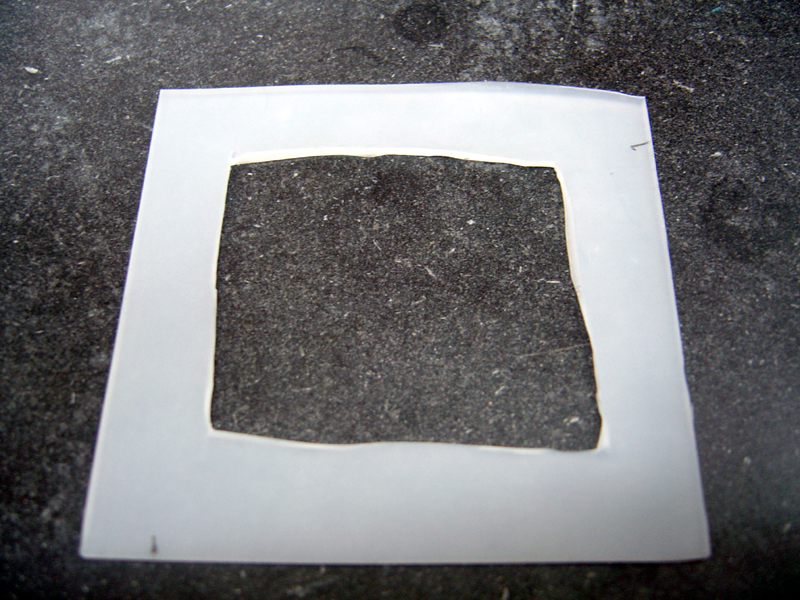

- 1" x 1" Nafion® membrane, 0.180mm thick

- 1" x 1" Carbon felt, 0.25" thick

- 1.5" x 1.5" E-TEK ELAT™ GDE (platinum on carbon)

- 2' Titanium Grade 2 Wire .046" Diameter

- Teflon Tape, 1/4" Width

- 5" x 2.5" Silicone Sheet

- Silicone Glue

- Spiral Point Tap 1/4"-28

- 8 Plastic Luer Lock Coupling Nylon, Female to Male Thread, 1/4"-28

- 8 Luer Lock Injection Ports

Procedure

- 1) Mill Polycarbonate

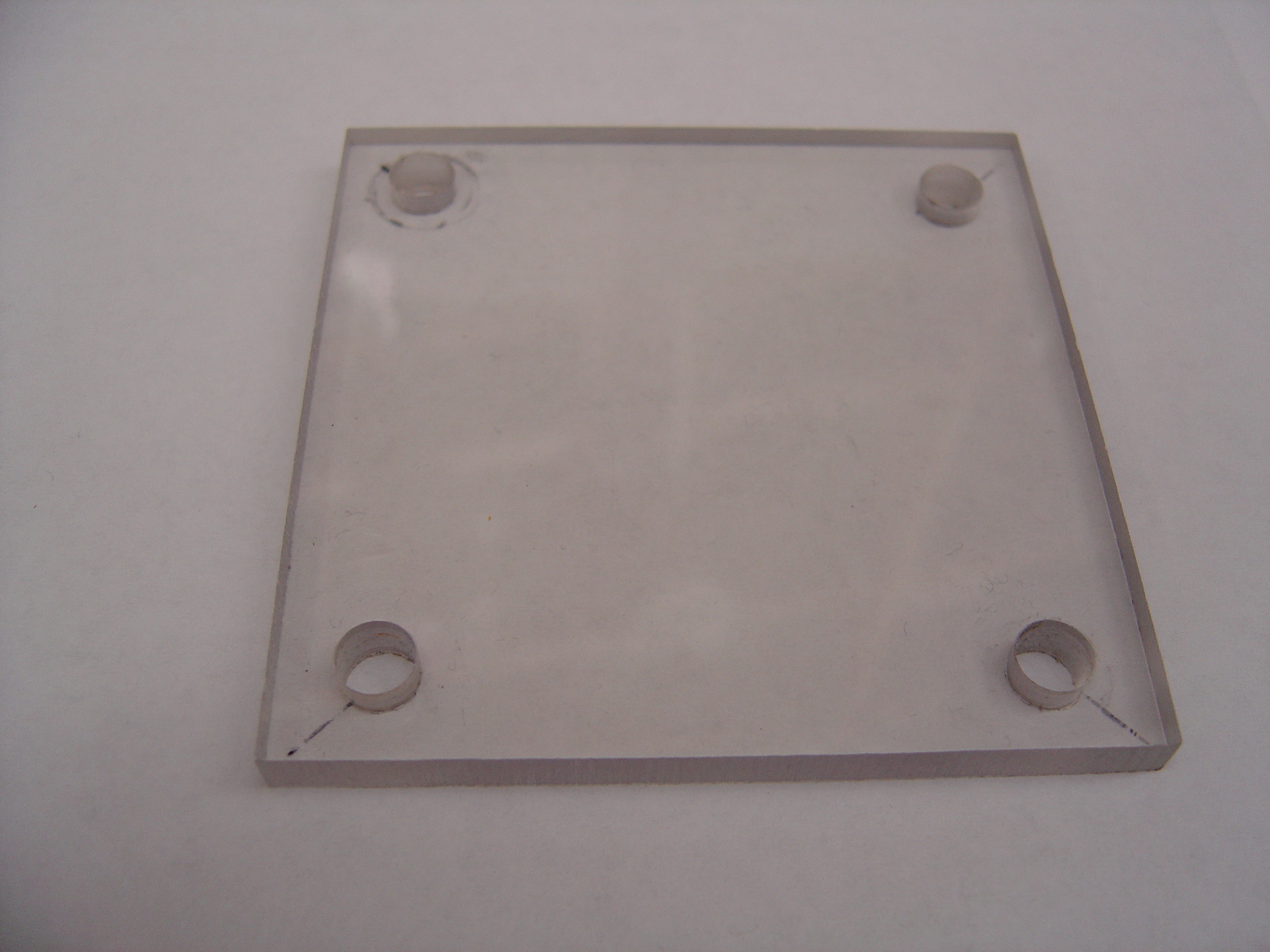

- Cut polycarbonate sheet into 4 equal 3" x 3" pieces

- Drill four 3/8" holes through each piece, 1 per corner, indented 5mm from both sides

- Cut polycarbonate tube into two equal 2" halves

- Drill four 1/4" holes through each half in configuration shown

- Tap each hole with 1/4" -28 spiral tap

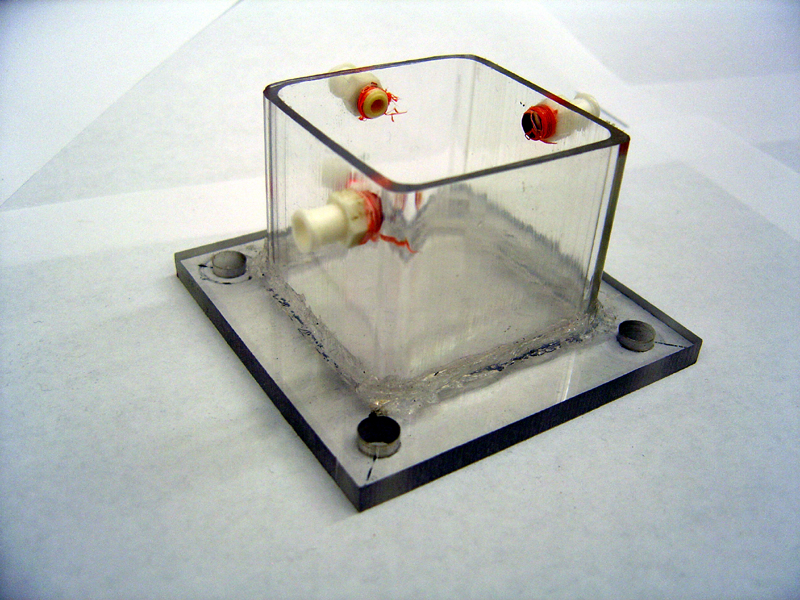

- 2) Glue Chambers (repeat for each half)

- Center tube on endplate by marking plate with 'X' from corner to corner

- Squirt 2mm thick line of silicone on edge of tube (edge furthest from holes)

- Press tube firmly against marked location on endplate

- Quickly spread excess silicone along edge

- Let stand 24h to harden

- 3) Construct Gaskets

- Cut silicone sheet into two equal 2.25" x 2.25" pieces

- Cut out centered inner squares in each piece, 1.75" x 1.75"

- Using inner squares, cut two 'O' rings, inner diameter 1/4", outer diameter 1/2"

- 4) Construct Electrodes

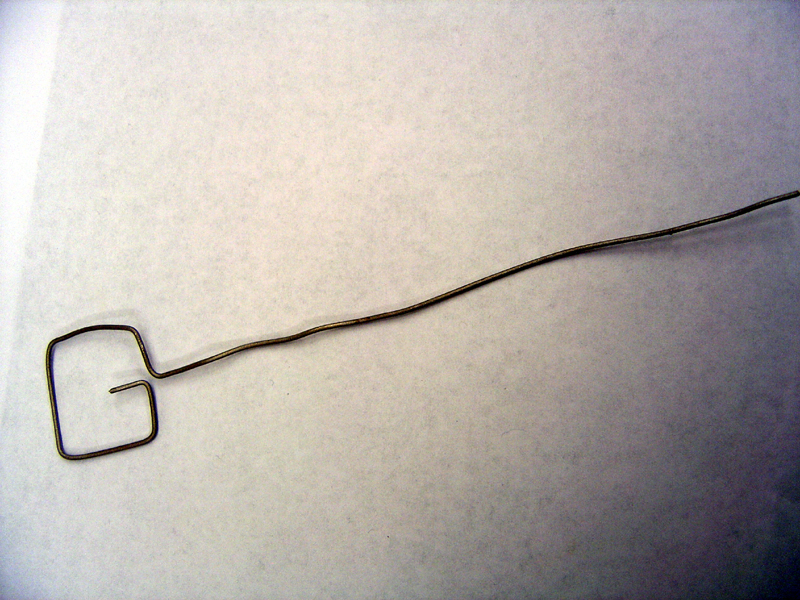

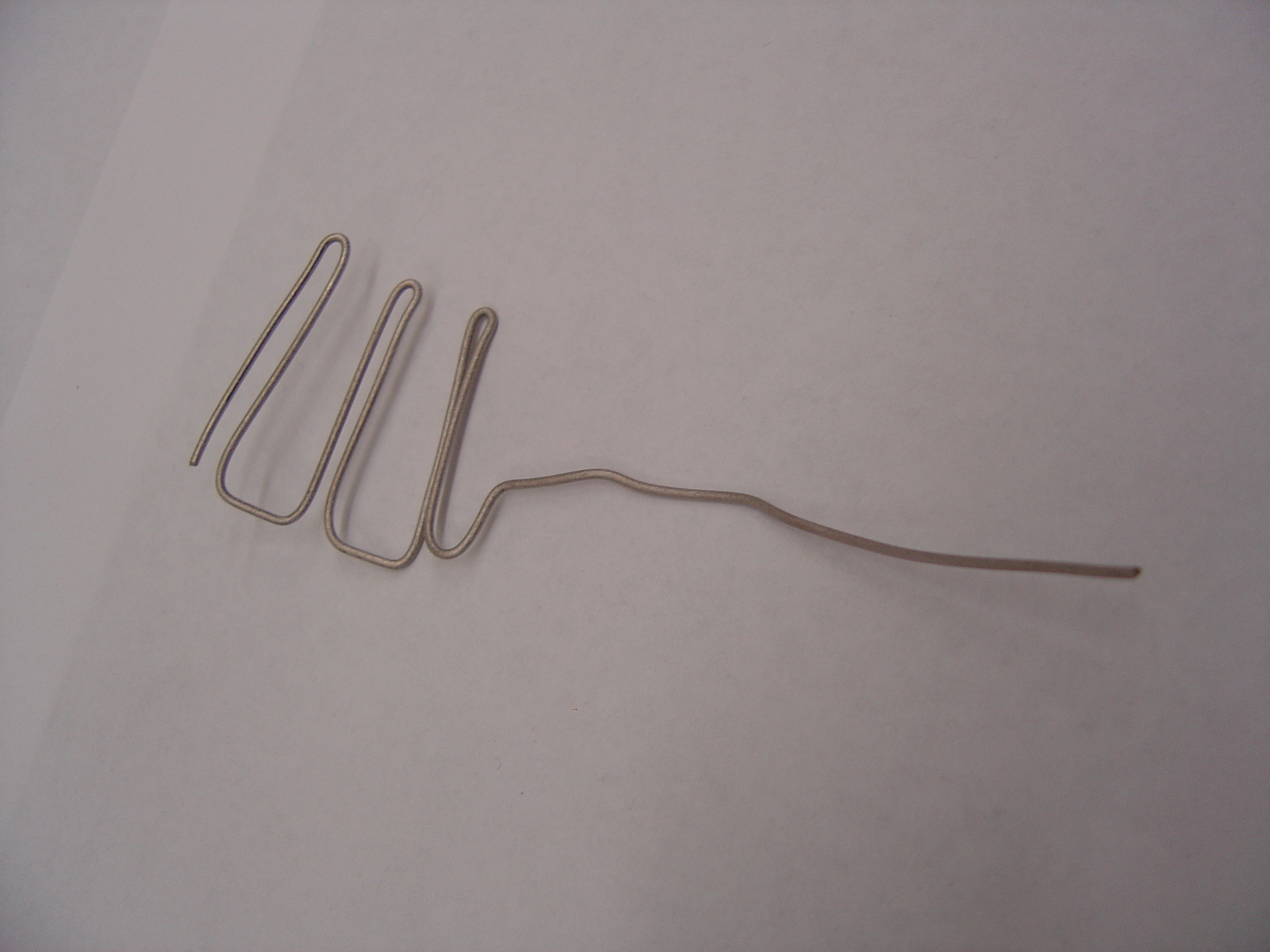

- Cut titanium wire into one 8" piece and one 16" piece

- Using pliers, shape anode and cathode as shown

Anode Frame

Cathode Frame

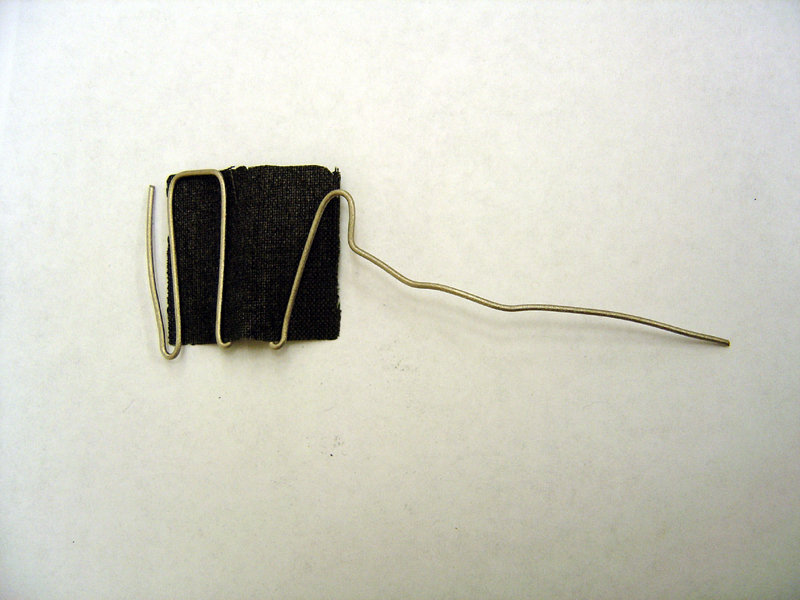

- Spear carbon felt with tip of anode titanium wire and wedge into frame

- Weave platinum carbon cloth through cathode titanium wire

Anode

Cathode

- 5) Seal Injection Ports

- Wrap threads of all eight Luer Lock screws with 1' of teflon tape in opposite direction of screwing

- Screw Luer Locks into all tapped holes in both chambers

Setup of Measurement Device

Materials

- Keithley 2700 Digital Multimeter

- Keithley 7700 Multiplexer

- Small Breadboard

- Supply of insulted thin copper wire

- 470 Ohm resistors (one/fuel cell)

Procedure

- Wire Multiplexer

- Open multiplexer, note channels

- Cut two wire 18" wire leads per fuel cell

- Strip ends, place one wire in each screw terminal, screw tight

- Tape paired wires (two are attached to each channel) near non-attached ends and label

- Clamp wire bundles near back of device with provided plastic latch clamps

- Close Multiplexer and slide into 2700 DMM

- Create Resistor Array

- Connect resistors across middle of breadboard (one per fuel cell)

- Connect leads from multiplexer across resistors (one pair across each resistor)

Controlling the DMM with LabVIEW™

- Initialize Multimeter

- Attach 2700 to COM1 port of desktop computer w/ LabVIEW™

- Download our LabVIEW™ source code MFCs.vi

- Open Program in LabVIEW™, adjust block diagram as necessary

Experiment Preparation

Begin 1 day prior to experiment

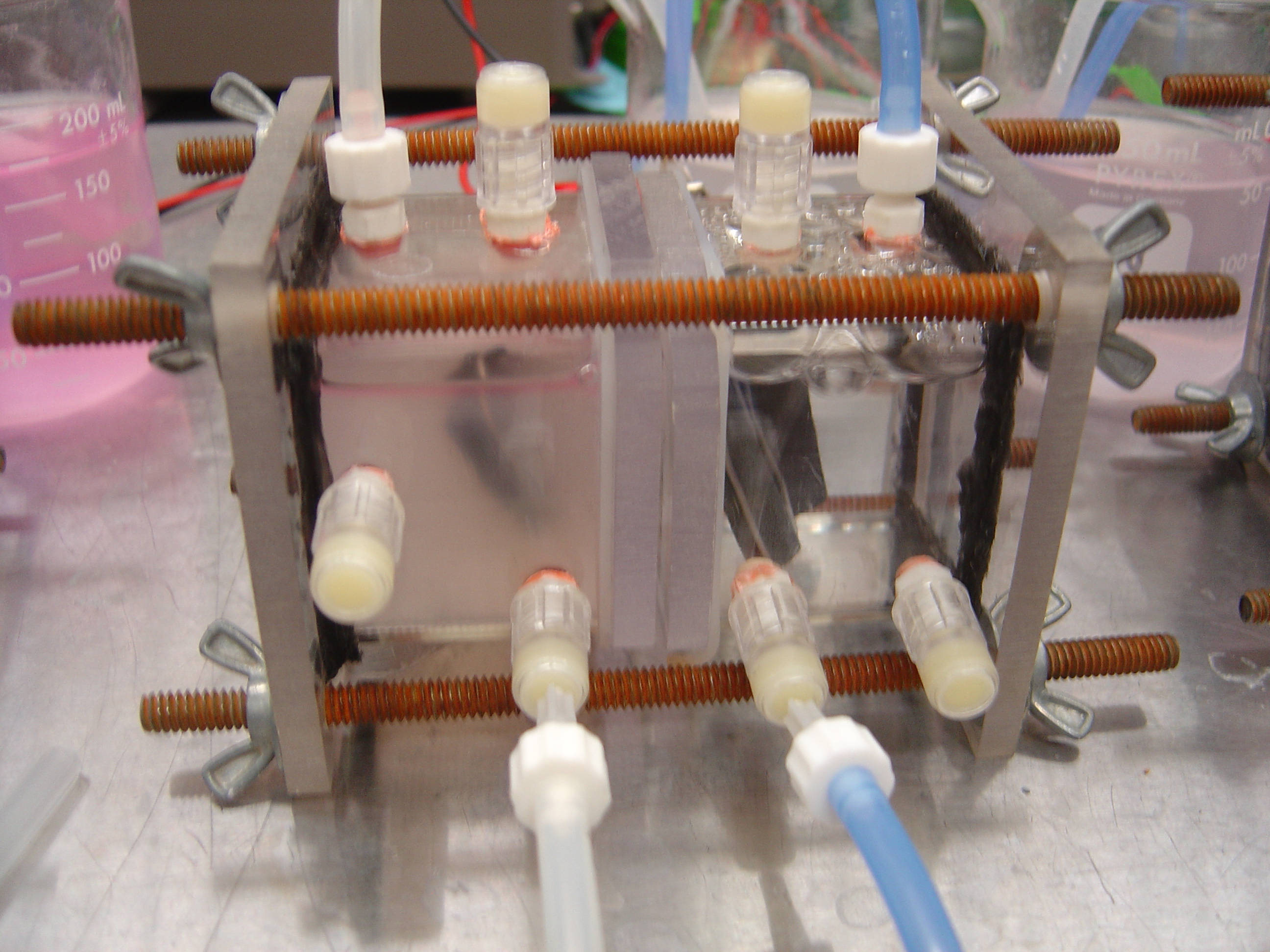

Assembling Chambers

Procedure

- Prepare Electrodes

- Attach Luer Lock injection ports to all chamber screws

- Poke tip of electrodes through designated ports from the inside

- Align Chambers

- Lay one chamber on a flat surface

- Place silicone square ring on top edge of tube

- Place polycarbonate square on silicone

- Place silicone 'O' ring around central pore

- Place Nafion membrane on top of 'O' ring

- Sandwich membrane between second 'O' ring

- Align second polycarbonate square on top of 'O' ring

- Center second silicone square ring on polycarbonate square

- Set second chamber on top of silicone, ensuring ports facing same direction as first chamber

- Clamp Chambers

- Move assembly into vice or clamp

- Insert rods through holes in end plates and screw on wing nuts

- Tighten evenly

Solutions Prep

- Chamber media (150ml / fuel cell)

- 5.844 g/L 100mM NaCl

- 15.1185 g/L 50mM PIPES (hydrogen)

- 7.0 pH

- Phosphate buffer (60ml / fuel cell)

- 2.918 g/L Monosodium phosphate, monohydrate

- 4.095 g/L Disodium phosphate, anhydrous

- 5.844 g/L 100mM NaCl

- 7.0 pH

Gas Tubing Assembly

Materials

- 25' Silicone Soft Rubber Tubing, 3/32" ID, 7/32" OD, 1/16" Wall

- Tank of Compressed Nitrogen

- Gas Regulator

- Lab Supply of Air

- 4 Plastic Luer Lock Coupling Nylon, Male X Barb, for 3/32" Tube

- 4 Plastic Luer Lock Coupling Nylon, Female X Barb, for 3/32" Tube

- Plastic Luer Lock Coupling Nylon, T junctions, for 3/32" Tube

- Syringe needles - 27 gauge

- 2 Aspirator Flasks

- 2 Rubber Stoppers

Procedure

- Make Flow Regulators

- Insert nozzle of female Luer Lock into rubber stoppers (poke hole if necessary)

- Cap aspirator flasks with rubber stoppers

- Attach tubing from gas sources to each glass nozzle of aspirator flask

- Make Manifolds

- Attach T-junction Luer Lock pieces into manifold (1 junction/ fuel cell ; 2 manifods total)

- Turn last juction such that off is facing end of manifold

- Attach tubing from stopper of flow regulators to beginning of each mainfold

Growing Strains

Materials

- 150mL LB / strain

- 1000mL airating flask / strain

- Antibiotics (if desired strain must be selected for)

- Plate or Glycerol Stock with desired strain

Procedure

- Fill flasks with LB

- Add correct concentration of selection antibiotic

- Pick single colony from plate, add to flask

- Incubate overnight in shaker at 30C

Runtime

Begin 2 hours prior to experiment

Bacteria

Procedure

- Pipet the cells out of the flask and into 250mL centrifuge containers

- Make sure the containers are close in weight (within 0.5g of each other)

- For a culture more than 250mL split it into two containers

- Set the centrifuge temperature to 22-23C, spin speed to 5000RPM, and time to 15 min

- After first spin, drain each container of the LB, making sure to leave the bacteria pellet intact

- Resuspend pellet in 50mL of potassium buffer

- After bacteria are fully resuspended (no pellets at all), spin down again, 22-23C, 5000RPM, 15min.

- Pour potassium buffer out of container slowly.

- Resuspend pellet in 50mL of potassium buffer

- Spin down again, 22-23C, 5000RPM, 15min.

- Pour potassium buffer out of container slowly.

- Resuspend pellet in 4 mL of sodium pipes

- Check OD (100microliters in 15mL or 1:150 dilution)

- If OD is in linear range, calculate dilution for desired quantity of bacteria in 1mL (typically 10^8 cells /mL of chamber media)

- Repeat dilution if not in linear range (using different ratio)

- Inject 1mL of bacteria into each chamber (see below)

Fuel Cells

Procedure

- Pipet 75mL of NaPiPES solution into each side of fuel cells

- Inject 1mL of Resazurin solution into each side of chamber

- Using Luer Lock nozzles, connect tubing from top ports to beaker w/ distilled water

- Cut tubing to span distance from manifolds to each fuel cell (1 from nitrogen, 1 from air)

- Attach syringe needles to tubing via Luer Lock nozzles

- Using Luer Lock nozzles, connect tubing from manifolds

- Start gas flow

- Poke needles through bottom ports on fuel cells

Measurements

Procedure

- Turn on computer and digital multimeter

- Open LabVIEW program

- Click Run arrow to take resistance readings

- Connect fuel cells to resistor array via alligator clips

- Click "Begin Current Readings" Icon on instrument display

Injections/Variables

Procedure

- Once current readings reach equilibrium, inject bacteria into fuels cells using syringes

- Allow bacteria to consume any carbon sources left in their media (approximately 12 hours)

- Once current levels reach stable baseline, inject 1ml lactate solution

- Inject additional variables as desired

Clean Up

Procedure

- Drain chambers and soak in 70% ethanol

- Remove carbon felt from anodes and discard (save titanium)

- Scrub all parts in ethanol and distilled water successively

- Use pipe cleaners on ports and tubes

|