Running an MFC Experiment

This page is intended as a comprehensive guide to completing a microbial fuel cell setup and running an experiment from start to finish.

Creating a Testing Environment

Begin 1-2 weeks prior to experiment

Constructing Fuel Cell Components

Materials (per fuel cell)

- 4" Polycarbonate Square Tube, 2" Outer Diameter

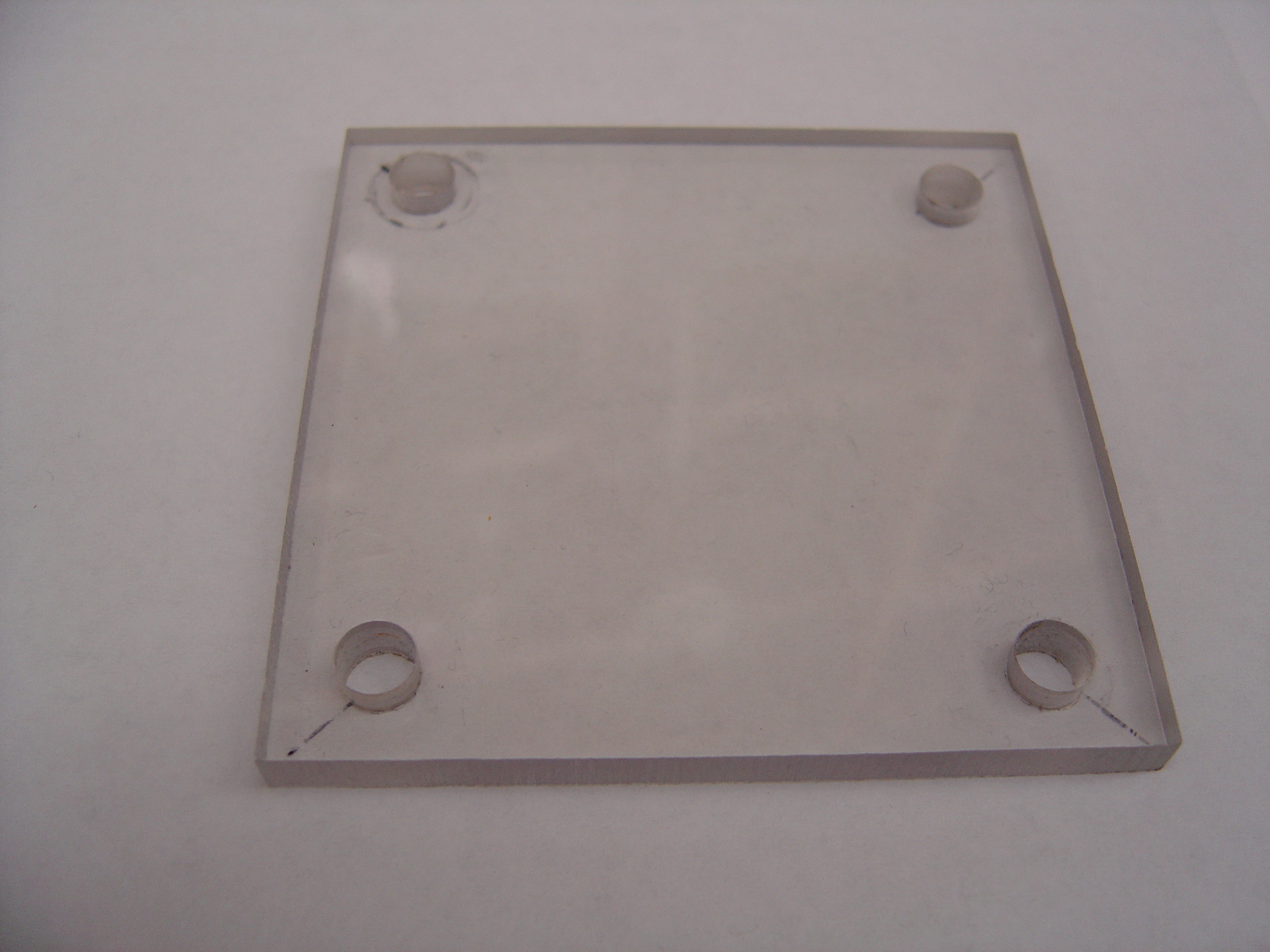

- 6" x 6" Polycarbonate Sheet, 1/4" Thick

- 4 Steel Fully Threaded Stud, 1/4"-20 Thread, 6" Length

- 8 Zinc Alloy Wing Flange Nut, 1/4"-20 Screw Size, 1" Wing Spread

- 1" x 1" Nafion® membrane, 0.180mm thick

- 1" x 1" Carbon felt, 0.25" thick

- 1" x 1" E-TEK ELAT™ GDE (platinum on carbon)

- 1' Titanium Grade 2 Wire .046" Diameter

- Teflon Tape, 1/4" Width

- 6" x 3" Silicone Sheet

- Silicone Glue

- Spiral Point Tap 1/4"-28

- 8 Plastic Luer Lock Coupling Nylon, Female to Male Thread, 1/4"-28

Procedure

- Mill Polycarbonate

- Cut polycarbonate sheet into 4 equal 3" x 3" pieces

- Drill four 3/8" holes through each piece, 1 per corner, indented 5mm from both sides

- Cut polycarbonate tube into two equal 2" halves

- Drill four 1/4" holes through each half in configuration shown

Setup of Digital Multimeter

Controlling the DMM with LabView™

Experiment Preparation

Begin 1 day prior to experiment

Assembling Chambers

Solutions Prep

Chamber media

- 5.844 g/L 100mM NaCl

- 15.1185 g/L 50mM PIPES (hydrogen)

7.0 pH

Phosphate buffer

- 2.918 g/L Monosodium phosphate, monohydrate

- 4.095 g/L Disodium phosphate, anhydrous

- 5.844 g/L 100mM NaCl

7.0 pH

Gas Tubing Assembly

Growing Strains

Runtime

Begin 2 hours prior to experiment

Bacteria

Fuel Cells

Injections/Variables

Clean Up

|