Team:UC Berkeley/LayeredAssembly

From 2008.igem.org

(→Layered Assembly) |

(→Layered Assembly) |

||

| Line 1: | Line 1: | ||

{{UCBmain}} | {{UCBmain}} | ||

==Layered Assembly== | ==Layered Assembly== | ||

| - | |||

| - | |||

| - | In layered assembly, a part is first biobricked into an entry vector. The part is then passed into the | + | In layered assembly, a part is first biobricked into an entry vector. The part is then passed into the appropriate assembly vector for 2 antibiotic assembly. A finished device may then be moved into a variety of destination vectors. |

| + | |||

| + | [[Image:layered Assembly.jpg|100px]] | ||

==Motivation== | ==Motivation== | ||

The reactions required to perform each step of layered assembly can be outsourced to engineered ''E. coli''. For example, to move a Biobrick part from an entry vector to an assembly vector usually requires digestion with the appropiate enzymes, gel purifying the correct fragment, then ligating the part with the assembly vector backbone. Using an ''E.coli'' with our Gateway device, this is reduced to just transforming the entry vector with the Biobrick part, lysing with the self-lysis device, and then using the lysate in a transformation. A protocol that cannot be easily automated is thus reduced to a series of liquid transfers and heating/cooling steps. | The reactions required to perform each step of layered assembly can be outsourced to engineered ''E. coli''. For example, to move a Biobrick part from an entry vector to an assembly vector usually requires digestion with the appropiate enzymes, gel purifying the correct fragment, then ligating the part with the assembly vector backbone. Using an ''E.coli'' with our Gateway device, this is reduced to just transforming the entry vector with the Biobrick part, lysing with the self-lysis device, and then using the lysate in a transformation. A protocol that cannot be easily automated is thus reduced to a series of liquid transfers and heating/cooling steps. | ||

Revision as of 06:08, 25 October 2008

Layered Assembly

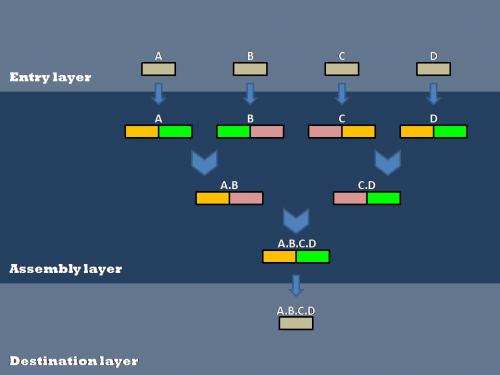

In layered assembly, a part is first biobricked into an entry vector. The part is then passed into the appropriate assembly vector for 2 antibiotic assembly. A finished device may then be moved into a variety of destination vectors.

Motivation

The reactions required to perform each step of layered assembly can be outsourced to engineered E. coli. For example, to move a Biobrick part from an entry vector to an assembly vector usually requires digestion with the appropiate enzymes, gel purifying the correct fragment, then ligating the part with the assembly vector backbone. Using an E.coli with our Gateway device, this is reduced to just transforming the entry vector with the Biobrick part, lysing with the self-lysis device, and then using the lysate in a transformation. A protocol that cannot be easily automated is thus reduced to a series of liquid transfers and heating/cooling steps.

"

"